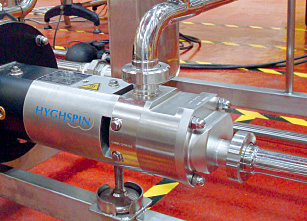

Advantages of HYGHSPIN pumps

SERVICEABILITY

-

1. Pumps with unique flexibility

Balanced rotors with low inertia permit a wide speed range up to 4000 rpm. One pump covers a large range of volume flows and viscosities. The pumps can be used for different media, and can simultaneously serve as CIP feed pump. The same pump can be used for different tasks.

-

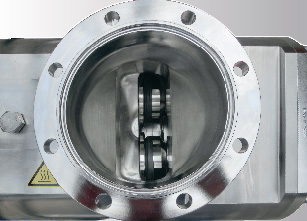

2. Gentle and practically pulsation-free pumping with excellent suction capacity

The product is moved axially, not centrifuged. For each screw revolution, the product is only moved along the space between screw flights, and not the rotors’ circumference. Low conveying speeds ensure gentle handling of sensitive products. The chambers are filled continuously on the suction side, and emptied on the outlet side. Consequently, product is conveyed almost pulsation-free, whereby the low turbulence ensures perfect suction capacity and a low NPSH value.

-

3. Highest hygiene level

HYGHSPIN pumps require no bypass for cleaning. The pumps are cleaned by the complete CIP flow. Hereby, the shafts are flushed reliably, because they are located in the main flow. This results in high flow speeds and significantly improved cleanability. The design is free of dead spaces, and is self-emptying. EHEDG and 3A certificates are available. Steam sterilisation (SIP) is possible without special measures.

-

4. Simple plant layout

Thanks to the flexibility of HYGHSPIN pumps, there is no need for a pump bypass or an external CIP feed pump. Valves and their controls are eliminated. Investment and service costs as well as the probability of downtimes due to component failure are reduced drastically.

-

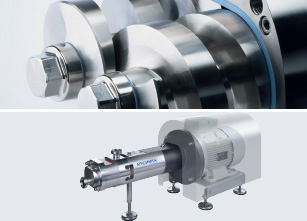

5. High wear resistance, no introduction of abraded particles into the product

The pumping components work contact-free. No abraded particles are introduced into the product. With corresponding shaft seals, the pump is dry-run safe. In combination with hardened pumping components, also very abrasive media can be conveyed. This leads to high availability and long service lives of the pumps.

-

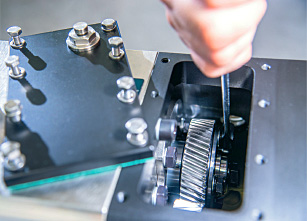

6. Corrosion-free & service-friendly design

HYGHSPIN pumps are made of stainless steel and are therefore corrosion-free. No grey cast iron components are used. This also ensures the external hygiene. Moreover, HYGHSPIN pumps are particularly service-friendly. Guide pins simplify assembly of the housing parts. Via an inspection opening, flank clearance of the feed screws can be checked directly, without having to disassemble the motor and gearbox housing.

-

7. Compact, operationally safe, and hygienic modular design

The modular design of HYGHSPIN pumps reduces the space required in the plant. Pump and motor shafts are aligned by means of positive fitting, so that damage due to misaligned or warped couplings is excluded. This increases operational safety. The shaft coupling is corrosion-protected, and the pumps are easier to clean from outside. Dirt accumulations under guard plates or a large base plate are prevented.

Let's stay in touch!

Contact us