Milk Powders

SUPPLYING GLOBAL MILK POWDER PLANTS

Here at GEA we understand that to manufacture high quality, free-flowing powdered dairy products you rely on robust, hygienic components and equipment, and safe, reproducible processing. As a producer you want to be confident that your processes are closely monitored and controlled, at every stage, to help maximize yield, reduce waste, and support sustainability.

And of course, our equipment and process solutions are designed to help ensure that from process start to end your products retain their key nutritional values and functional properties, such as agglomeration and stability. Working with GEA you can be confident that your plant will help you to achieve maximum productivity from key ingredients, with fewer bottlenecks and delays.

Resource-saving solutions for environmentally sensitive processing

GEA works closely with the industry to identify new opportunities for saving energy and resources, and for improving environmental sustainability. We have developed versatile technologies, including heat pumps and process-critical cooling systems, that can reduce resource use, cut waste, and where possible recycle heat and water. Some of the largest milk powder plants delivered by GEA feature processes that extract water from the milk during evaporation, and then filter and recycle the water for use elsewhere in the plant.

Hygienic plant design and efficient cleaning

Of course, all GEA technologies are designed to meet the latest food hygiene, quality and safety standards. Our durable, maintenance-friendly plants can be cleaned thoroughly and efficiently using CIP (clean-in-place) systems that can save on water and detergent use and so reduce costs. Automated cleaning frees personnel to carry out other key tasks, and enables faster cleaning cycles. Combined benefits include increased productivity with fewer delays. Reducing downtime means improved plant utilization, which can ultimately increase the return on your investment and reduce the total cost of ownership. GEA solutions can also help you to ensure full and transparent traceability of raw materials and ingredients, throughout the process and into the final product.

Because we understand your key challenges, we have developed and offer state-of-the-art components, equipment and complete lines that we believe will help optimize each stage of your processes, from milk treatment and ingredients dosing, to the finer points of mixing and spray drying. You can trust GEA to take care of the smallest detail.

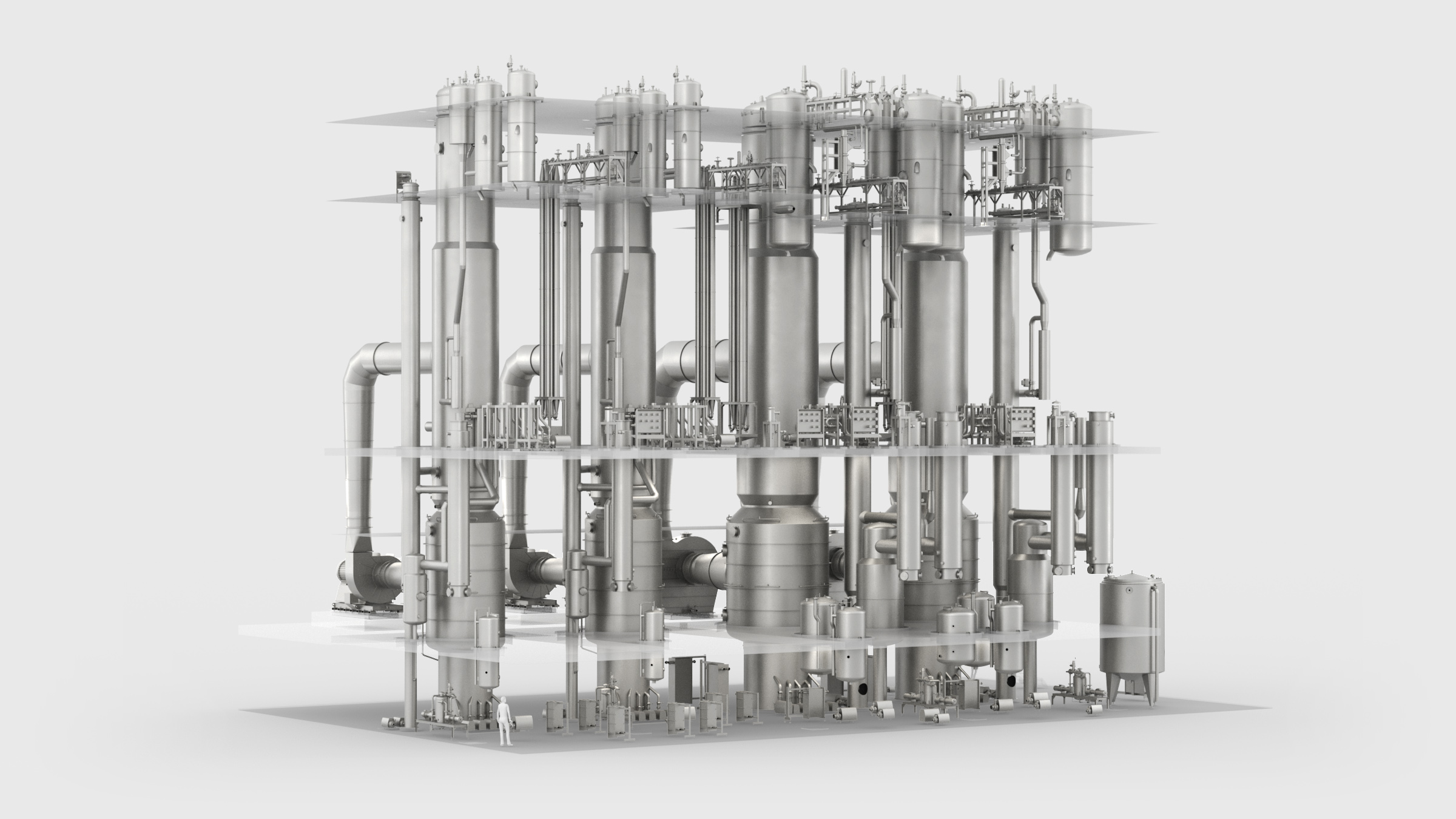

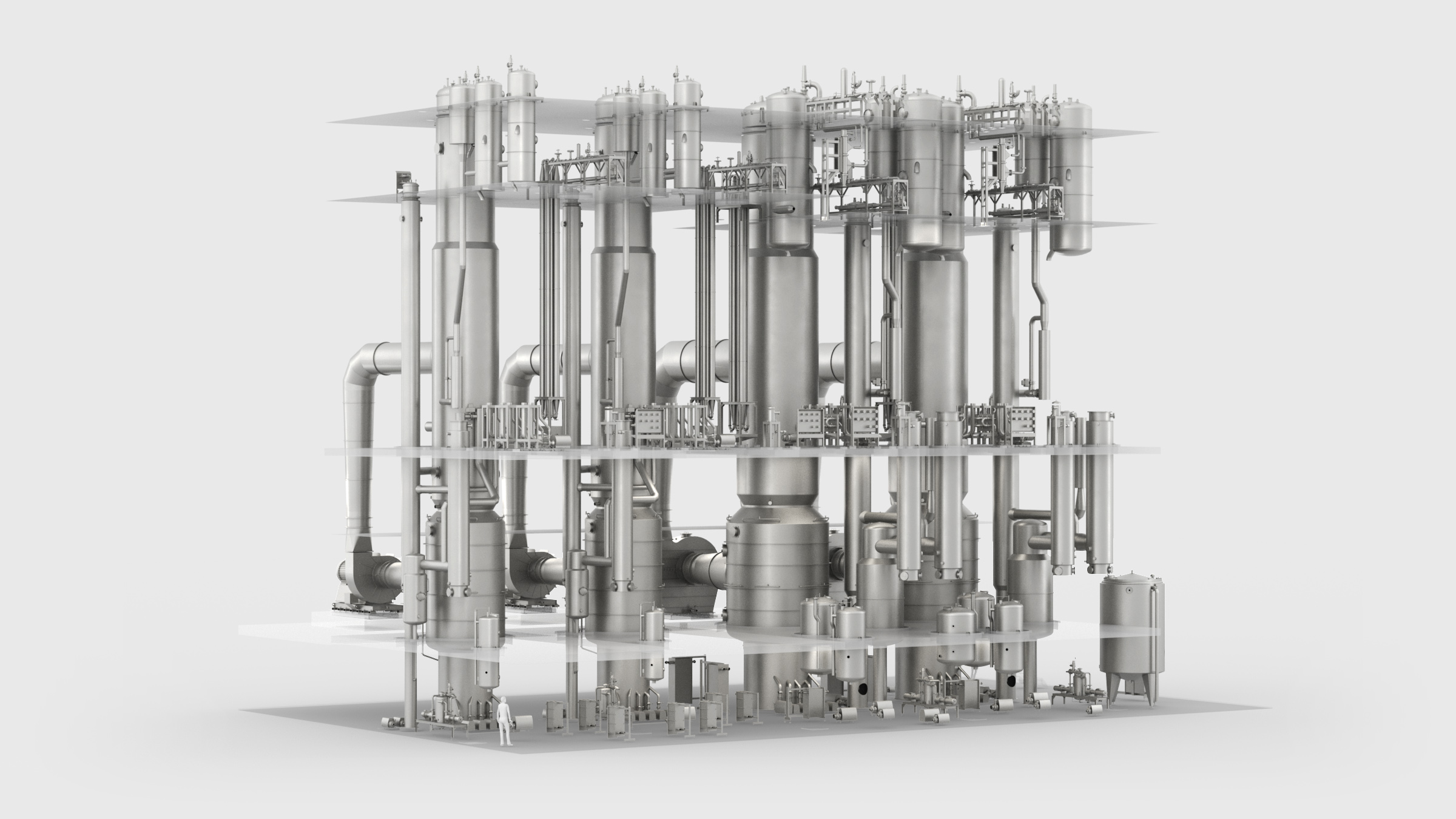

Process line for milk powder

-

1. Cream separation & standardization

Raw milk, vegetable oils and other liquid ingredients such as whey-based products are stored and are gently and hygienically handled on being received into the plant. Ahead of further formulation, raw milk typically undergoes cream separation with optional subsequent standardization. Besides the continuous control of the standardized milk fat content, the automatic standardization units can also provide a continuous control of the cream fat content and a proportional dosing of additives.

-

2. Pasteurization & bacteria removal

GEA provides a range of technologies to reduce or remove bacteria and spores from liquid ingredients, ensuring sensitive products remain undamaged and the highest levels of microbiological safety are achieved. Pasteurization as traditional heat treatment reduces bacteria and spores, whereas bacteria removal separators and microfiltration remove them.

-

3. Dry ingredients storage & handling

The HYGiTip is a core element in our complete bag handling and emptying solution. When configured with de-palletizing/outer stripping, sterilization, powder handling, dust collection and waste management, plant operators are able to let this automated solution run continuously with minimal supervision, increasing OEE and enabling personnel to concentrate on other value-added tasks. A typical plant solution may include: de-palletizing, outer bag removal, UV sterilization, automatic bag emptying, powder handling and waste removal.

-

4. Lactose mixing & standardization

The addition of Lactose is typically achieved via a standard funnel mixer, following which the product is passed through a holding tube to ensure it is fully dissolved. The mix is then regeneratively cooled before being chilled to <8°C and finally sent to storage. To achieve decoupling of lactose tipping and dosing operations, storage tanks are carefully sized. As an alternative, lactose powder can be dissolved directly into the milk at the standardized milk storage tanks. This process is similar to that employed when the powder is dissolved into water or inline using a vacuum mixer.

-

5. Pre-concentration by filtration

As an option, the skimmed milk can be pre-concentrated by RO. The degree of concentration depends on the heat treatment required and end-product characteristics, and must therefore be considered on a specific project basis. The process will run cold at 5-8 °C for up to 20 hours between CIP.

-

6. Evaporation

Further heat treatment is applied to the formulated product on the evaporator using a number of different solutions to ensure both stability and microbiological safety. Our low thermophile system, UHT technology, direct steam injection and steam infusion technologies are examples thereof. The product is then further concentrated ahead of being dried using a falling-film evaporator.

-

7. Homogenization

In dairy applications it is common for high pressure homogenizers to be used. This is due to their ability to apply dynamic high-pressure energy to break particles in the fluid down to the smallest, potentially nanometer-scale size. As a result of this high pressure homogenization process, an emulsion is created that is stable when the mix is concentrated, dried, packed and resolubilized by the end customer.

-

8. Spray drying

For the final removal of moisture to produce a dried powder, a GEA MSD® Spray Dryer is recommended for milk powder. The resulting spray drying process produces consistent, precisely defined functional powders with uniform bulk density and robust agglomerates and that are readily re-dissolved in water. The MSD® benefits from a new CEE cyclone design, which allows customers to maximize fines recovery while minimizing smearing and energy use. Our fines system requires zero intervention and allows fully automated CIP, reducing the risk of contamination and ensuring less downtime on the dryer.

-

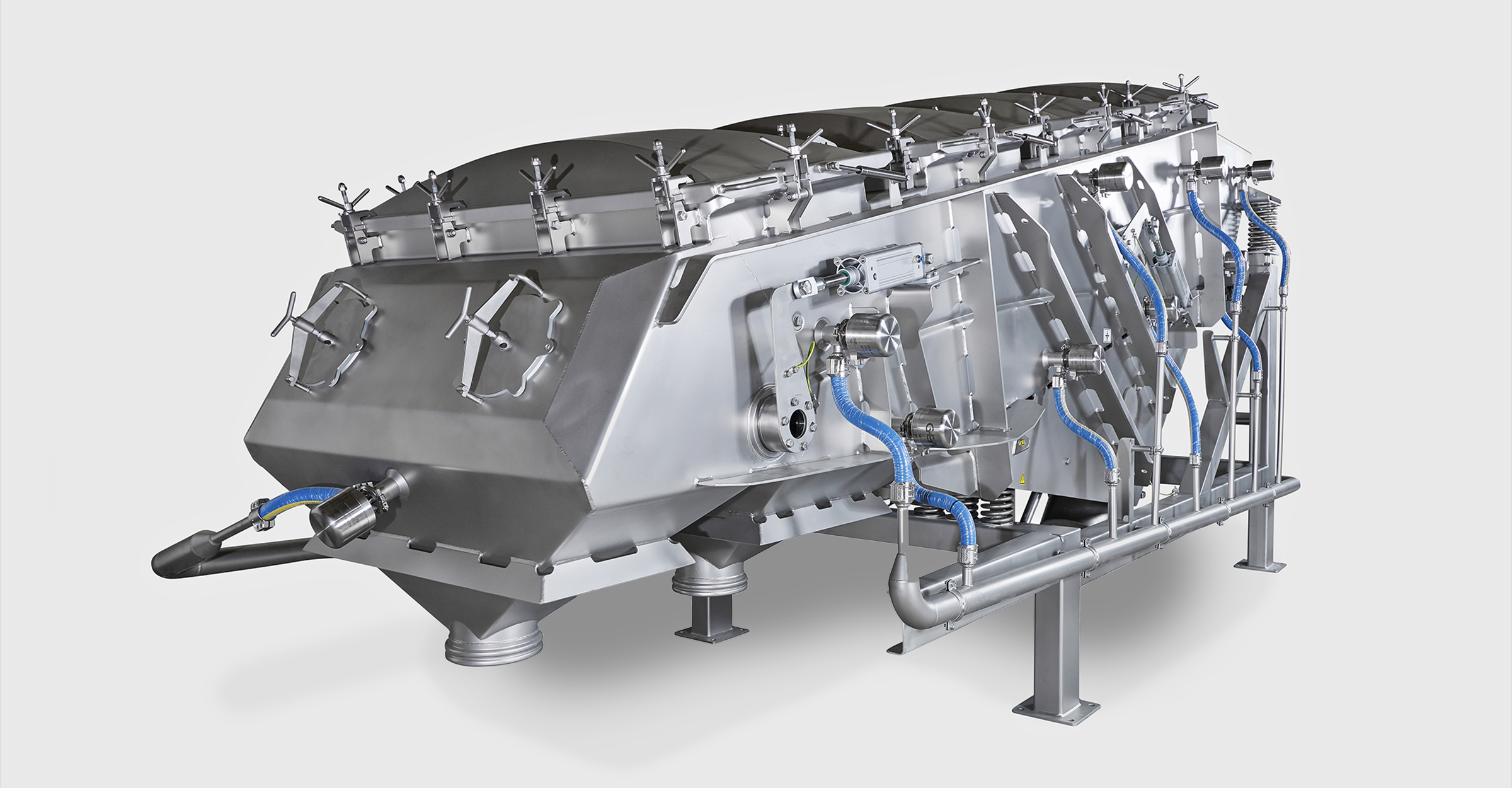

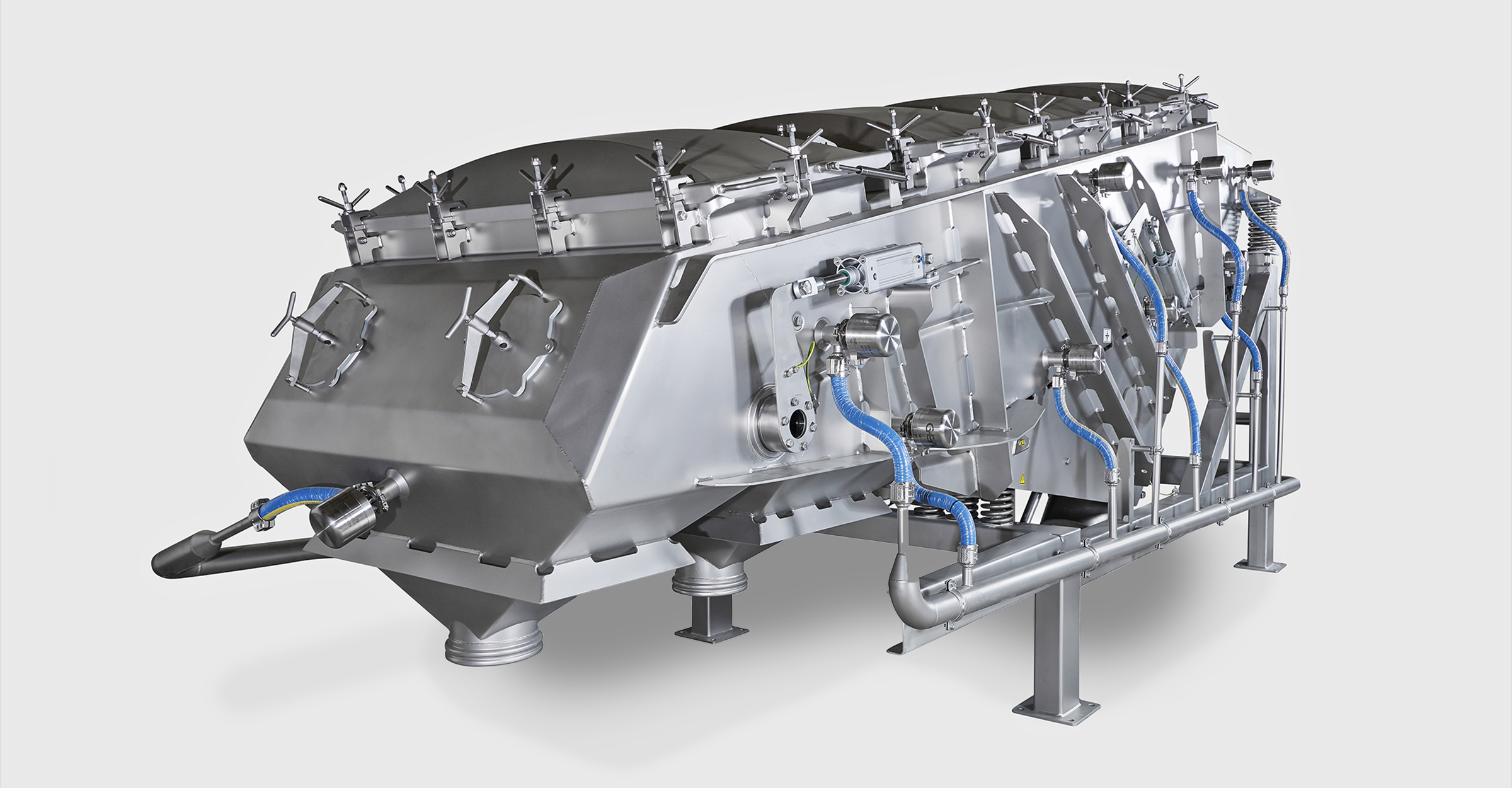

9. Powder handling

Using a GEA Scan-Vibro vibrating screen the dried powder is sifted to remove oversized particles before being gently conveyed to storage using either dense phase conveying or gravity to minimize breakdown of the powder. To minimize interstitial air the powder is drawn under vacuum and is flushed with nitrogen before packing. The result is a powder that has an enhanced shelf life due to its very low residual oxygen content.

-

10. Powder filling & palletizing

For Modified Atmosphere Packing (MAP) into 25kg bags or bulk containers, GEA offer a range of powder filling solutions. To improve overall operational efficiency whilst reducing labor demand, GEA 25kg Limited Intervention (Li) filling machines feature fully automated bag handling. For customers that require a turnkey solution, manual or automated palletizing options are also available for integration.

-

11. Refrigeration & heating

GEA in-house experts have extensive experience of integrating smart cooling & heating solutions into the complete milk powder process. Customers benefit from lower energy consumption, minimized operating costs, increased sustainability and reduced carbon footprint, in addition to having full confidence in GEA as a trusted partner.

-

12. Automation

To ensure optimum efficiency and performance, GEA technologies can be configured with full automation. For example, the GEA Codex® solution delivers full and transparent traceability of both raw material and ingredients throughout the entire process and into the final product.

-

1. Cream separation & standardization

Raw milk, vegetable oils and other liquid ingredients such as whey-based products are stored and are gently and hygienically handled on being received into the plant. Ahead of further formulation, raw milk typically undergoes cream separation with optional subsequent standardization. Besides the continuous control of the standardized milk fat content, the automatic standardization units can also provide a continuous control of the cream fat content and a proportional dosing of additives.

-

3. Dry ingredients storage & handling

The HYGiTip is a core element in our complete bag handling and emptying solution. When configured with de-palletizing/outer stripping, sterilization, powder handling, dust collection and waste management, plant operators are able to let this automated solution run continuously with minimal supervision, increasing OEE and enabling personnel to concentrate on other value-added tasks. A typical plant solution may include: de-palletizing, outer bag removal, UV sterilization, automatic bag emptying, powder handling and waste removal.

-

5. Pre-concentration by filtration

As an option, the skimmed milk can be pre-concentrated by RO. The degree of concentration depends on the heat treatment required and end-product characteristics, and must therefore be considered on a specific project basis. The process will run cold at 5-8 °C for up to 20 hours between CIP.

-

7. Homogenization

In dairy applications it is common for high pressure homogenizers to be used. This is due to their ability to apply dynamic high-pressure energy to break particles in the fluid down to the smallest, potentially nanometer-scale size. As a result of this high pressure homogenization process, an emulsion is created that is stable when the mix is concentrated, dried, packed and resolubilized by the end customer.

-

9. Powder handling

Using a GEA Scan-Vibro vibrating screen the dried powder is sifted to remove oversized particles before being gently conveyed to storage using either dense phase conveying or gravity to minimize breakdown of the powder. To minimize interstitial air the powder is drawn under vacuum and is flushed with nitrogen before packing. The result is a powder that has an enhanced shelf life due to its very low residual oxygen content.

-

11. Refrigeration & heating

GEA in-house experts have extensive experience of integrating smart cooling & heating solutions into the complete milk powder process. Customers benefit from lower energy consumption, minimized operating costs, increased sustainability and reduced carbon footprint, in addition to having full confidence in GEA as a trusted partner.

-

2. Pasteurization & bacteria removal

GEA provides a range of technologies to reduce or remove bacteria and spores from liquid ingredients, ensuring sensitive products remain undamaged and the highest levels of microbiological safety are achieved. Pasteurization as traditional heat treatment reduces bacteria and spores, whereas bacteria removal separators and microfiltration remove them.

-

4. Lactose mixing & standardization

The addition of Lactose is typically achieved via a standard funnel mixer, following which the product is passed through a holding tube to ensure it is fully dissolved. The mix is then regeneratively cooled before being chilled to <8°C and finally sent to storage. To achieve decoupling of lactose tipping and dosing operations, storage tanks are carefully sized. As an alternative, lactose powder can be dissolved directly into the milk at the standardized milk storage tanks. This process is similar to that employed when the powder is dissolved into water or inline using a vacuum mixer.

-

6. Evaporation

Further heat treatment is applied to the formulated product on the evaporator using a number of different solutions to ensure both stability and microbiological safety. Our low thermophile system, UHT technology, direct steam injection and steam infusion technologies are examples thereof. The product is then further concentrated ahead of being dried using a falling-film evaporator.

-

8. Spray drying

For the final removal of moisture to produce a dried powder, a GEA MSD® Spray Dryer is recommended for milk powder. The resulting spray drying process produces consistent, precisely defined functional powders with uniform bulk density and robust agglomerates and that are readily re-dissolved in water. The MSD® benefits from a new CEE cyclone design, which allows customers to maximize fines recovery while minimizing smearing and energy use. Our fines system requires zero intervention and allows fully automated CIP, reducing the risk of contamination and ensuring less downtime on the dryer.

-

10. Powder filling & palletizing

For Modified Atmosphere Packing (MAP) into 25kg bags or bulk containers, GEA offer a range of powder filling solutions. To improve overall operational efficiency whilst reducing labor demand, GEA 25kg Limited Intervention (Li) filling machines feature fully automated bag handling. For customers that require a turnkey solution, manual or automated palletizing options are also available for integration.

-

12. Automation

To ensure optimum efficiency and performance, GEA technologies can be configured with full automation. For example, the GEA Codex® solution delivers full and transparent traceability of both raw material and ingredients throughout the entire process and into the final product.

Products & technologies

Please contact us for information on relevant products

Let's stay in touch!

Contact us