Gasketed Plate Heat Exchangers

Gasketed Plate Heat Exchangers

GASKETED PLATE HEAT EXCHANGERS

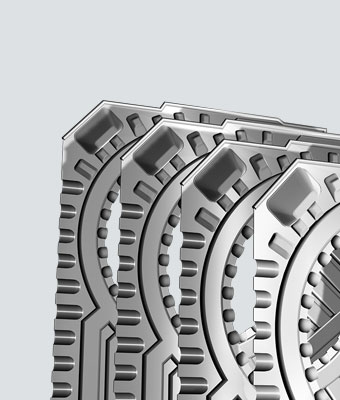

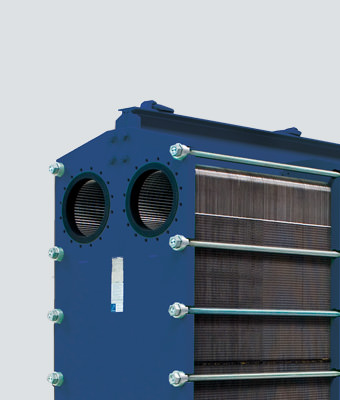

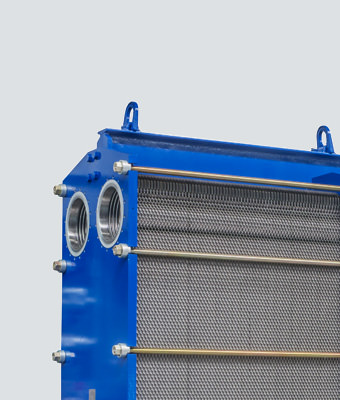

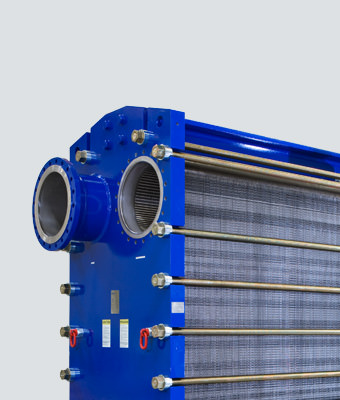

Our gasketed plate heat exchangers combine passion, scientific curiosity and technological expertise. The facts: High efficiency at low operating costs, versatile application possibilities with lower investment costs and maximum flexibility. Our efforts to continuously develop the gasketed plate heat exchanger-series further are aimed at meeting your thermodynamic and hydraulic performance needs and to ensure maximum economic efficiency. Our wide range of plate corrugations, connection sizes, materials, plate lengths and widths enable an ideal configuration according to your exact requirements. Additionally, our gasketed plate heat exchangers come with a maintenance-friendly assembly and sealing technology, ensuring low service and maintenance costs.

IN ADDITION TO THESE COMMON APPLICATIONS, OUR GASKETED PLATE HEAT EXCHANGERS ARE ALSO SUITABLE FOR:

- chemical process cooling

- media containing fibres and solids (e.g., in the sugar and paper industry)

- highly viscous media (e.g., dairy and other food products)

- healthy drinking water treatment and purification

- secure cooling for power plants with river or seawater

- demanding climate control solutions (e.g., for data centers)

- condensation or evaporation (e.g.,in refrigeration, sugar or chemical industries)

Our heat exchanger specialists are happy to make a thermodynamic calculation and a design draft of the appropriate unit for your application. Contact our distribution & sales team with their expert know-how in products and processes for a comprehensive heat exchanger consultation, today. Our experts can also offer you the best service for your gasketed plate heat exchanger.

Let's stay in touch!

Learn more about innovations and our products, by signing up to our newsletter.

Contact us

We are here to help! With just a few details we will be able to respond to your inquiry.