Quality and Flexibility

PLATE HEAT EXCHANGERS / PLATE COOLERS

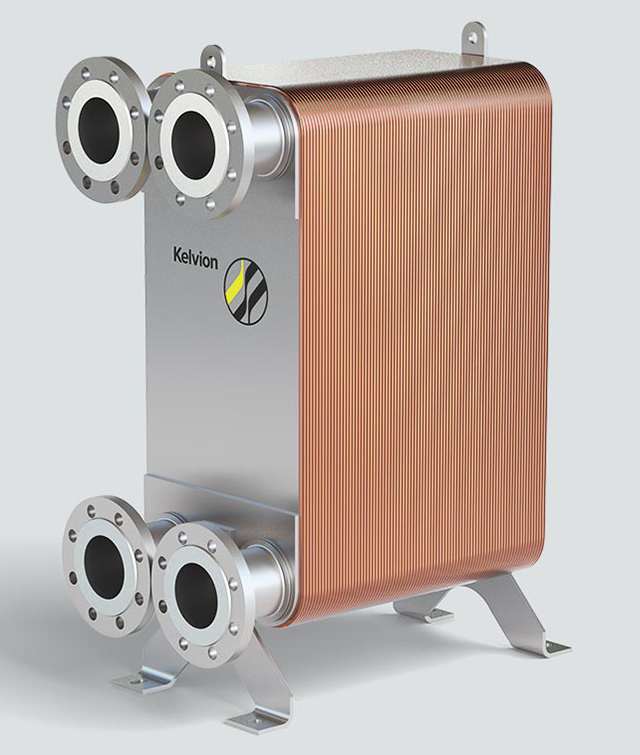

PLATE HEAT EXCHANGER: DEFINITION AND FUNCTION

Plate heat exchangers are used to transfer heat between two media, which are separated from each other by corrugated plates. The plate heat exchanger consists of different heat transfer plates, which are sealed by gaskets, or brazed, or welded together.

The heat exchanger’s individual transfer plates are arranged in packages, which form flow channels through which the hot and cold media alternatingly flow. This enables the thermal energy to transfer from one media to the other. It is essential that the two media are securely separated from each other (e.g., by seals) to avoid mixing. Whenever the heat exchanging media flow in opposite directions, as is usually the case, we speak of the countercurrent principle. Otherwise, the flow principle is parallel. Some fully-welded models may also apply the cross-flow principle. Common to all variants is that the special corrugation of the transfer plates ensures a highly turbulent flow behavior.

Plate heat exchanger: design and application

In principle, all of our plate heat exchangers function similarly. Depending on the purpose for which the heat exchanger is needed, they may differ in configuration, structure and materials used. Brazed plate heat exchangers are small and compact and used preferably within the HVAC industry and refrigeration industry. Gasketed plate heat exchangers can be flexibly adapted and, if necessary, extended to optimally meet our customer’s requirements. This is particularly essential in the chemical, food and marine industry. Welded plate heat exchangers, in comparison, are designed for high pressure and temperatures, thus preferably used in oil and gas applications.

Additional examples of application areas are:

- heating technology, e.g. underfloor heating, solar systems or DHW heating

- industry, e.g. in power plants or in mechanical engineering

- food technology, e.g. for cooling milk or for pasteurizing beer

- refrigeration and cooling technology, e.g. as a condenser, evaporator or superheater

Just ask us – we will gladly advise you with selecting the most suitable plate heat exchanger for your application or show you the suitable service solution.

Let's stay in touch!

Contact us