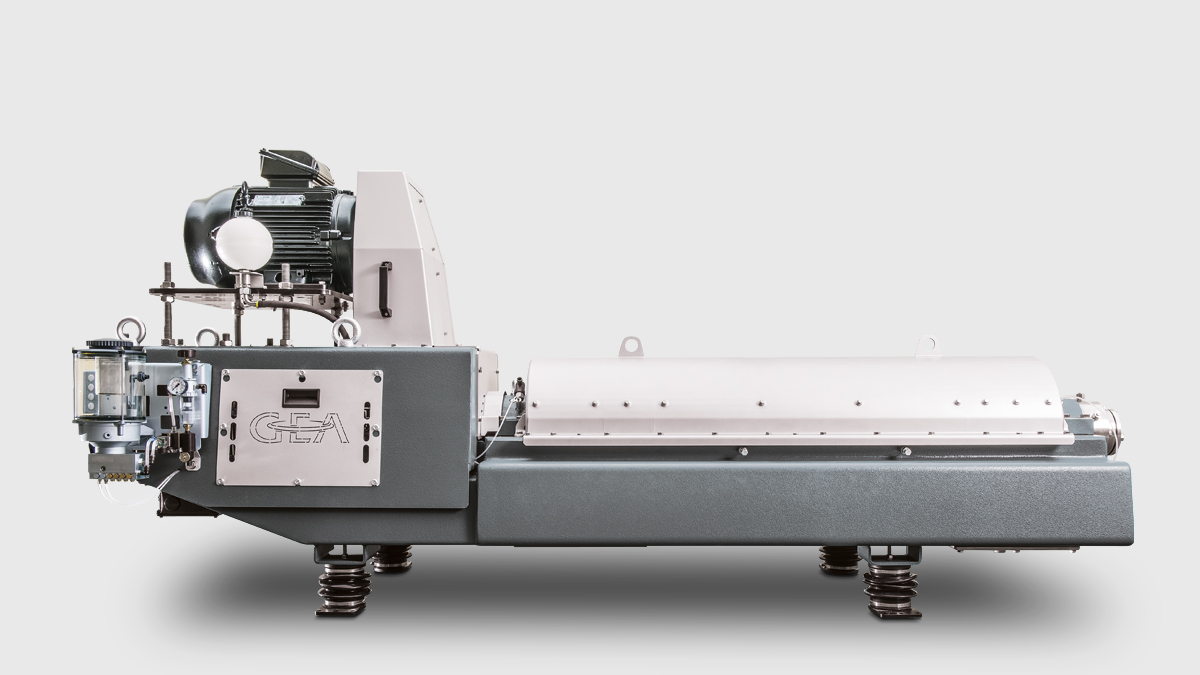

CLARIFYING DECANTERS FOR EDIBLE OIL REFINING

The decanter separates the solids from the oil in fully continuous operation. Solids are discharged continuously which results in a continuous solids recycling into the press.

Using a decanter combines foots removal with partial degumming, in case of chemical refining the result of this combination of two process steps is often sufficient. On top, GEA decanters are easy to operate and automate and they need only little space. With their robust design our decanters can handle oil temperatures of up to 105° C. The external gears which segregates product from drive room, oil lubrication of all bearings, special materials and high quality wear make our GEA ecoforce decanters especially suited for hot applications and continuous heavy duty.

Features & Benefits

- Continuous solids separation

- Low cost of automation

- Lower space requirement

- Simultaneous degumming

- Rugged and robust design

- External gear concept of GEA ecoforce decanters

- Oil lubrication of all bearings

Related videos

Let's stay in touch!

Contact us