Brewing Systems

BREWING SYSTEMS

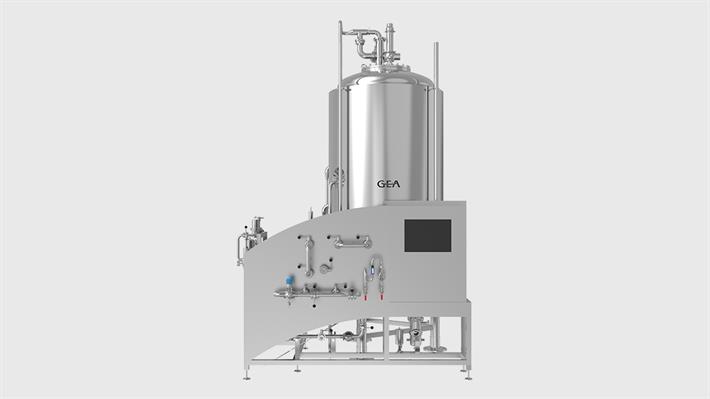

When it comes to brewing technology, GEA is the specialist. With our extensive know-how and vast engineering experience we are uniquely qualified to build brewery plants. Like no other supplier, GEA covers the complete brewing process in the finest detail – from the mill to the valve manifold of the bright beer tanks. This level of attention gives you exceptional security in terms of operation, process design and spare parts.

Products

Showing

Let's stay in touch!

Learn more about innovations and our products, by signing up to our newsletter.

Contact us

We are here to help! With just a few details we will be able to respond to your inquiry.