Home & personal care

KEEPING CLEAN WITH GEA PROCESSES

The home and personal care (HPC) industry serves fast-growing, brand-driven markets for products as diverse as shampoo, body lotion, shower gel and toothpaste to laundry detergents and all-purpose cleaners. Consumer demand for better value, high performing products that keep us healthy and our clothes, homes and cars clean and fresh. Driving industry innovation in this competitive, but potentially highly profitable marketplace.

GEA understands the pressures facing HPC manufacturers. Product launch deadlines and the need to meet targets for reducing water and energy consumption put extra pressure on process development. Manufacturing must be adaptable to incorporate improvements and new ingredients or develop preservative free and other market-led formulations.

GEA combines more than 70 years of industry know-how with global expertise, local insight and presence to provide efficient, sustainable solutions that HPC manufacturers need to stay competitive in their markets. But we don’t just supply machines. We combine conceptual design and project planning, with engineering and commissioning, to configure innovative, industry-leading technologies and state-of-the-art plants for your high performance HPC processing. Tailored automation and utilities supply ensure seamless, end-to-end solutions that meet all your requirements.

Customers can even carry out feasibility trials and scale-up studies at GEA’s worldwide test centers, to help address manufacturing issues and develop new processes.

GEA technologies give the industry the freedom to develop new and exciting products and thus deliver sustainable manufacturing solutions not just today, but for the future:

- Sustainable manufacturing solutions

- Repeatable processing

- Manufacturing more products in less time

- Energy efficient solutions

- Product personalization

Products & technologies

-

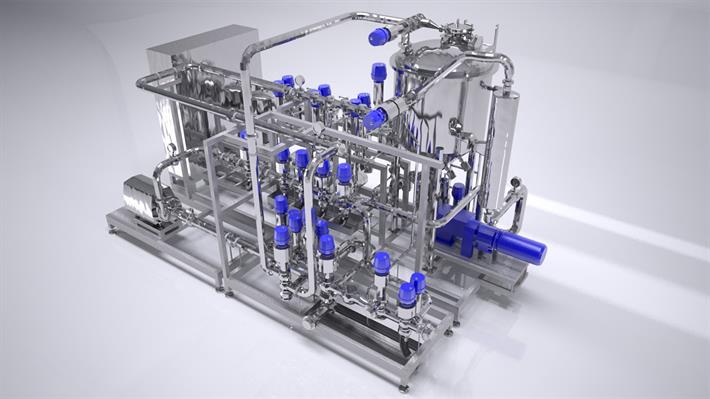

Showing 2 of 11Automation & Control SystemsDiversity is one of nature’s key concepts to cope with changing and variable environments. This strategy is also a strength in automation: different environments and trades need different solutions and individual adaptations. Whether in the brewing, chemical, dairy or pharmaceutical industries, automation and control systems have different requirements and need individualized solutions.

-

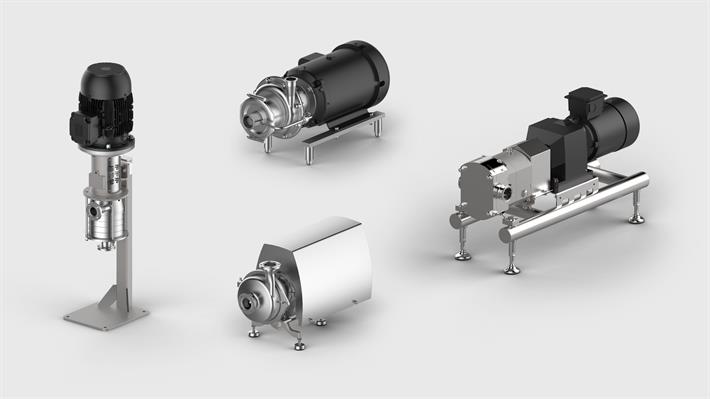

Showing 3 of 11HomogenizersThe equipment needed by the homogenizer includes all the components able to micronize the particles of the fluid and to obtain a homogenous and stable emulsion of the product. Industrial and laboratory high pressure homogenizers are positive displacement pumps equipped with the compression block and the homogenizing valve able to process a wide range of applications and to enhance the organoleptic characteristics and the stability of the product.

-

Showing 3 of 11Mixers & BlendersGEA's extensive process knowledge and continuous research delivers the most efficient mixers and blenders. We offer a wide range of technical solutions and process options to ensure the efficient mixing and blending of liquids, powders and granules for a broad scope of industries and applications. Our range of high-performance mixers and wide range of capacity options means you can choose a machine that exactly matches your processing requirements. From food, beverage and dairy applications to chemical, personal care and pharmaceutical ones, whether batch or continuous, GEA not only understands mixing technology, we also have a unique understanding and know-how of the entire process, based on many years of experience and hundreds of successful installations.

-

Showing 3 of 11

Let's stay in touch!

Contact us