ALCOHOL-FREE BEER

Keep the Taste

Modern processes may use one of several methods to either completely remove or significantly reduce the amount of alcohol in beer. Primarily, these methods involve either stopping the fermentation process using a centrifugal separator (mechanical separation) that swiftly removes the yeast from beer at the right moment or using techniques such as evaporation (a thermal method), or membrane filtration (mechanical separation), to remove the alcohol.

Here at GEA, we offer the industry technologies backed by 145 years’ of experience in end-to-end brewery processes. Today we are one of the most experienced manufacturers of both mechanical and thermal separation solutions for producing dealcoholized or alcohol-free beer. Breweries around the world trust GEA to provide solutions and support for every stage of the production process. Using tailored, cost-effective GEA systems, breweries of any size can look to optimize their existing processes, and innovate with exciting new recipes to generate market-winning filtered, and unfiltered alcohol-free beers that will become firm favorites with consumers.

Importantly, we don’t just offer technologies for removing or reducing the alcohol content, we use our in depth knowledge of the brewery industry and its processes and markets, to help ensure that our customers invest in the best solutions for their products, and to match business expectations, existing plant setup, and capacity.

In a nutshell, we provide:

- GEA beer separators that are used to remove the yeast from the alcohol free beer after a short contact time between yeast and beer. The fermentation then is stopped. These machines can be used multifunctional for green beer or mature beer clarification

- GEA reverse osmosis, cross flow membrane filtration systems, that work at low temperatures, so they are really gentle on the product, and generate both the alcohol-free beer product, and also an alcohol solution that can be used as a basis for other, flavored beverages.

- Gentle evaporation systems that work at relatively low temperatures, and which help to ensure efficient recovery of key aromatics, to help ensure that alcohol-free beers retain the taste and aromas that discerning consumers expect.

Products & technologies

- Brewing Systems

- Centrifuges & Separation Equipment

- Cleaners & Sterilizers

- Membrane Filtration Systems

- Mixers & Blenders

- Valves & Pumps

-

Showing 1 of 7Brewing SystemsWhen it comes to brewing technology, GEA is the specialist. With our extensive know-how and vast engineering experience we are uniquely qualified to build brewery plants. Like no other supplier, GEA covers the complete brewing process in the finest detail – from the mill to the valve manifold of the bright beer tanks. This level of attention gives you exceptional security in terms of operation, process design and spare parts.

-

Showing 1 of 7Centrifuges & Separation EquipmentSince 1893, GEA has been building centrifuges which combine high separating efficiencies, clarifying efficiencies and throughput capacities with maximum savings in terms of energy, water and disposal costs.

-

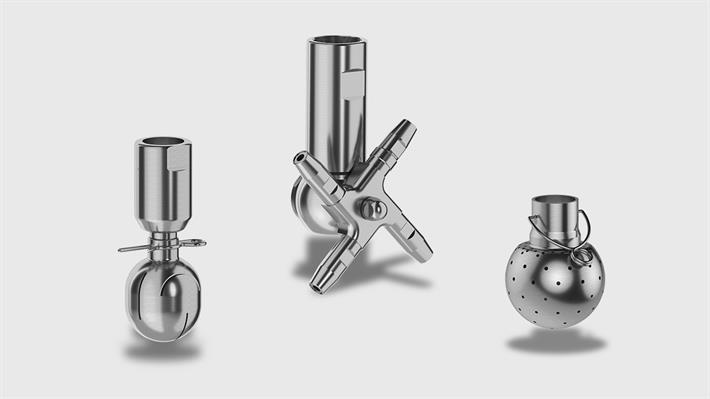

Showing 1 of 7Cleaners & SterilizersIn today's processing industries, from food and beverage to personal care, from dairy to pharmaceutical, integrated clean-in-place (CIP) solutions play a key role. GEA supplies both manual and fully automated CIP and sterilize-in-place (SIP) solutions, ensuring reliable process outcomes with minimal downtime. Whether it's liquid, solid or semi-solid, GEA’s extensive range of cleaning and sterilization solutions — from R&D to full-scale production and from standalone equipment and modules to completely integrated processing lines — are an essential requirement for any quality conscious manufacturer. We also recognize the increasing need to handle highly potent and toxic actives, guarantee both operator and product safety, prevent batch-to-batch cross-contamination and protect the environment.

-

Showing 1 of 7Membrane Filtration SystemsCross-flow membrane filtration, including nanofiltration, microfiltration, ultrafiltration and reverse osmosis, is the technology of choice for many industrial processes that require the separation or concentration of products without the application of heat. There are applications throughout the food, dairy, beverage, chemical, biotechnology, fermentation, as well as starch and sweetener industries in which membrane filtration excels.

-

Showing 1 of 7Mixers & BlendersGEA's extensive process knowledge and continuous research delivers the most efficient mixers and blenders. We offer a wide range of technical solutions and process options to ensure the efficient mixing and blending of liquids, powders and granules for a broad scope of industries and applications. Our range of high-performance mixers and wide range of capacity options means you can choose a machine that exactly matches your processing requirements. From food, beverage and dairy applications to chemical, personal care and pharmaceutical ones, whether batch or continuous, GEA not only understands mixing technology, we also have a unique understanding and know-how of the entire process, based on many years of experience and hundreds of successful installations.

-

Showing 2 of 7