SEPARATORS FOR MILK AND WHEY SKIMMING

In all areas of processing, there are applications for dairy separators such as warm and cold milk separation, whey separation, buttermilk separation, cream concentration and butter oil concentration and polishing.

Skimming separators with GEA hydrosoft feed system

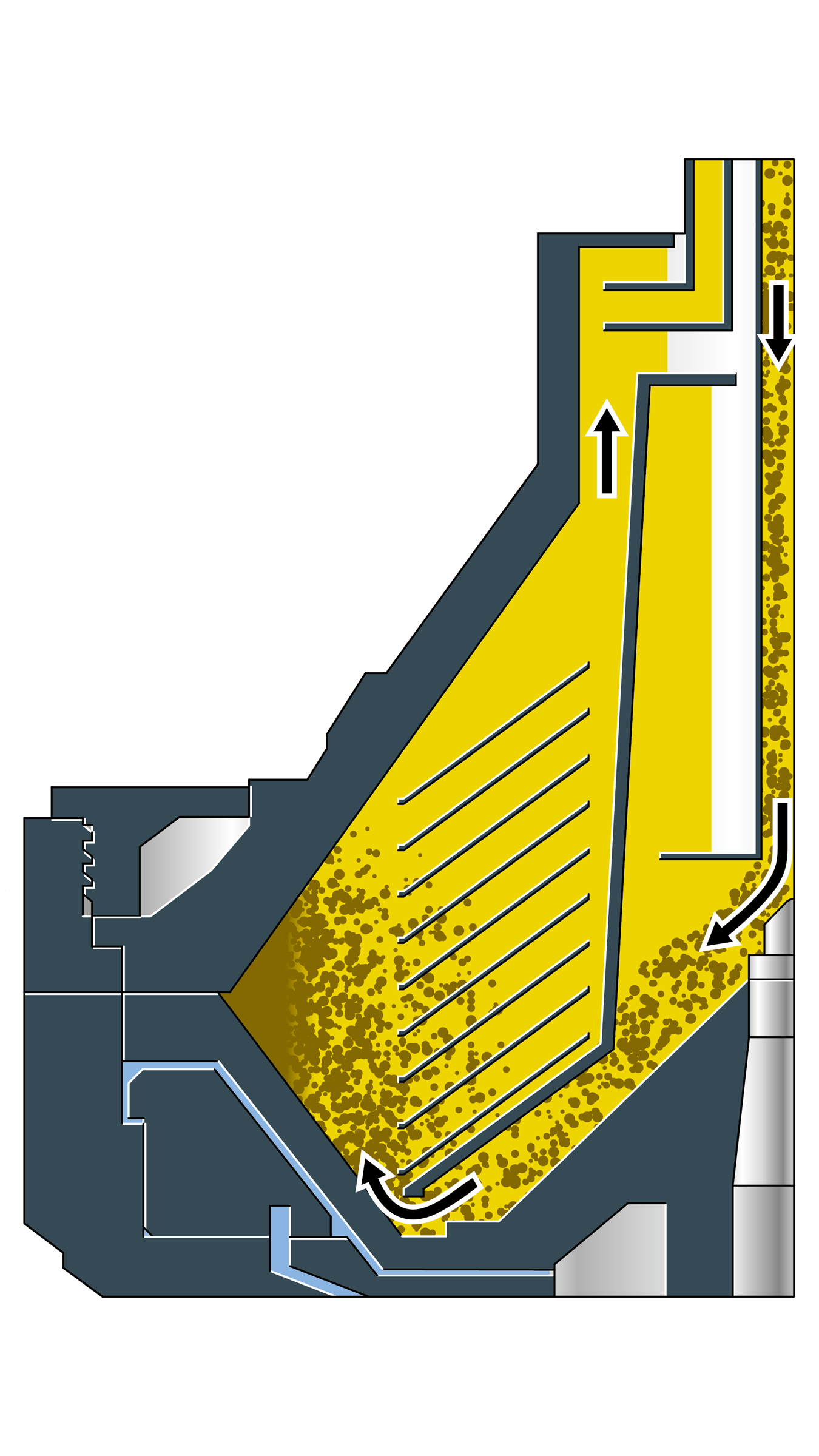

The hydrosoft feed system combines the advantages of the GEA softstream system with those of the hydrohermetic feed system. Combining these systems allows very gentle acceleration of the product at a low pressure level. The system offers a high degree of flexibility in terms of feed capacity. Owing to the cream centripetal pump situated above the system, which is immersed in the cream during production, the inlet chamber is hydrohermetically sealed off from the outer air. Air intake into the product is therefore not possible. The stationary feed tube allows the product to flow into the centrally-located bore of the rotating distributor The central bore has no ribs so avoids shear effect on the product. The product is gently fed through the radially arranged bores into the inner rising channels of the disk stack where it is separated into skim milk and cream.

GEA CleanSkimmer for whey skimming

New range of skimming centrifuges in special design

The heart of a whey processing line is usually a skimming separator for the removal of fat from whey. These centrifuges can only process a limited amount of cheese fines and must be complemented by an upstream clarifying separator to maintain a good skimming performance.

When feed conditions vary regularly, the new GEA CleanSkimmer gets into the game, which is not only suitable for whey, but is also the first choice for milk with an increased non-milk solids content. This specially designed centrifuge is capable of satisfactory skimming efficiency even at increased cheese fines loads without the need of a clarifying separator upfront.

GEA’s new “workhorse” thus not only facilitates the processing of whey, but also the skimming of milk with a higher content of non-milk solids content.

Increased fat recovery even at higher cheese fines loads

For cheese manufacturers, processing residual whey is no longer an option but a mandatory task if they not only want to avoid high disposal costs but also strive to complete their portfolio with high-value products such as whey protein isolates.

And there are many good reasons for removing the remaining fat from the whey as completely as possible.

High fat recovery means

- more additional value stream

- better, low-fat protein concentrate or isolate

- longer operating time and better performance of downstream equipment, such as membrane filtration

Especially when different types of whey need to be processed and when a higher cheese fines concentration may only be expected from time to time, the investment of a premium clarifier and skimmer combination might be difficult to justify.

In this case, the newly designed GEA CleanSkimmer is just the perfect match, delivering satisfactory skimming results while being tolerant against increased solids loads.

Designed for stable skimming efficiency

A special bowl design prevents solids with a concentration of up to 0.2 % vol. from clogging the centrifuge. The GEA CleanSkimmer can thus be operated at a reasonable discharge frequency while maintaining a stable skimming efficiency of up to 0.06 % fat in skim whey/milk.

Product portfolio

Type Capacity

GEA CleanSkimmer 100 up to 15,000 l/h

GEA CleanSkimmer 140 up to 20,000 l/h

GEA CleanSkimmer 180 up to 25,000 l/h

GEA CleanSkimmer 230 up to 30,000 l/h

GEA CleanSkimmer 350 up to 35,000 l/h

GEA CleanSkimmer 400 up to 40,000 l/h

GEA CleanSkimmer 500 up to 50,000 l/h

GEA CleanSkimmer 600 up to 55,000 l/h

GEA CleanSkimmer 700 up to 60,000 l/h

Cold milk separation by GEA procool

The markets for cold milk separation are expanding dynamically; the same is true for the earnings potential of efficient dairies.

GEA procool

Dairies, particularly in the USA, Mexico, Australia and New Zealand, are increasingly using cold milk separation for skimming purposes.

Separating milk in this way allows dairies to comply with their customers’ quality requirements for products such as milk powder and drinking milk. Cold milk separation with GEA procool satisfies this requirement both in terms of the physical and microbiological properties of these products. procool also stands for a new and permanent optimum efficiency throughout the entire process of cold milk separation.

Minimum Energy Input, Maximum Product Quality

procool has been developed with the benefit of over 125 years of experience in the milk processing industry and technology leadership in mechanical separation technology. procool fully develops the overall benefits of cold milk separation:

- Improvement of the bacteriological nature of the end product by cold treatment of the raw milk

- Energy savings as there is no requirement for heat

- Reduction in denaturing of proteins (WPNI ≥ 6mg N/g)

- Production of specific products according to the customer‘s specifications

In addition to these benefits, the procool innovation sets new standards in terms of throughput capacity, separating efficiency, process reliability and effectiveness of cold milk separation.

Technical Features & Capacities

GEA offers separators with flat belt drive (types MSE, GEA ecocream and GEA milk Skimmer pro) and integrated direct drive (type MSI). Our self-cleaning separators are for applications that require continuous processing. Separation takes place in the disk stack; the solids are separated out in the solids holding space.

Capacities

Type MSE:

- Skimming: 10,000 – 60,000 l/h

- Cold milk skimming: 3000 l/h – 50,000 l/h

- Standardizing: 10,000 – 75,000 l/h

- Cream concentration: 2000 – 25,000 l/h

- Butter oil concentration and polishing: 1000 – 21,000 l/h

Type GEA ecocream:

- Skimming: 3000 – 10,000 l/h

- Standardizing: 3000-15,000 l/h

- Cream concentration: 1000 – 2000 l/h

Type GEA milk Skimmer pro:

- Skimming: 2000 l/h – 5000 l/h

- Standardizing: 2000 l/h – 7500 l/h

Type MSI:

- Skimming: 10,000 – 60,000 l/h

- Standardizing: 10,000 – 75,000 l/h

- Cream concentration: 2000 – 25,000 l/h

Standard scope of delivery

Types MSE / MSI / ecocream:

- 3-phase AC motor

- Foundation frame

- Special tools

- Basic spare parts

- Gear oil

Additionally for type MSI:

- Motor control (MCC)

- GEA condition monitoring for pro-active maintenance

Additionally for type ecocream:

- GEA proplus system for extending ejection intervals

Type

GEA milk Skimmer pro:

- GEA hydrostop system:

- Automatic solids discharge at full bowl speed and open feed. This makes it possible to integrate the machine in the CIP process.

Commissioning spare parts:

- Lubricants and gaskets for commissioning

- Set of bowl top gaskets

- Flat belt

- Initial filling of lubrication oil

Special tools

- Set of special tools for dismantling and assembling of the machine

Options

Types MSE / MSI / ecocream:

- Solids tank or solids discharge

- Feed flow control

- Back pressure control

- Cream flow control

- Process control (PLC)

Additionally for types MSE / MSI:

- GEA standomat for cream fat content and milk standardizing

- GEA proplus system for extending ejection intervals

Additionally for type MSE:

- Motor control (MCC)

- GEA condition monitoring for pro-active maintenance

Additionally for type MSE (cold milk):

Preheater for adjustment of the product temperature

Type milk Skimmer pro:

Valves:

- Set of manual valves and indicating instruments for the adjustment of feed, skim milk discharge pressure and cream flow as well as the continuous standardizing of milk and cream fat content. Milk cleaning (complete re-blending) and full skimming are possible as well.

Control system:

- Manual motor starter

Related videos

Let's stay in touch!

Contact us