NOZZLE SEPARATORS FOR STRAINED YOGHURT, QUARK AND FRESH CHEESES

The latest generation of GEA nozzle separators was designed especially for manufacturing fresh cheese products and their efficient and economic operation is convincing. The continuously operating centrifuges enable a repeatable product quality with minimized product losses, increased yield precise setting of the fresh cheese texture or the total solids percentage – and everything fully automatic and user-friendly!

A product’s success is based firstly on its exceptional quality, here: a “natural” flavor and a creamy and smooth “mouthfeel”. Compared to traditional manual and time-intensive methods, whey is today separated with the aid of GEA centrifuges at 10,000 times the force of gravity in order to obtain the desired product – with a quality and taste that equals the original in its full-bodied creaminess.

Customer benefits

Depending on the individual process, our centrifuges offer decisive advantages, for example compared with the membrane filtration process:

- Constant flow rate

- Constant product characteristics (e.g. with respect to texture or total solids)

- Option of direct filling after concentration

- Easy integration into existing process line

- Quick and easy adaptation of total solids

- Option of integration into an existing CIP line

- Long operating times (minimum 16 hours) compared with alternative processes

- No addition of stabilizers and powders required

Highly efficient and flexible production

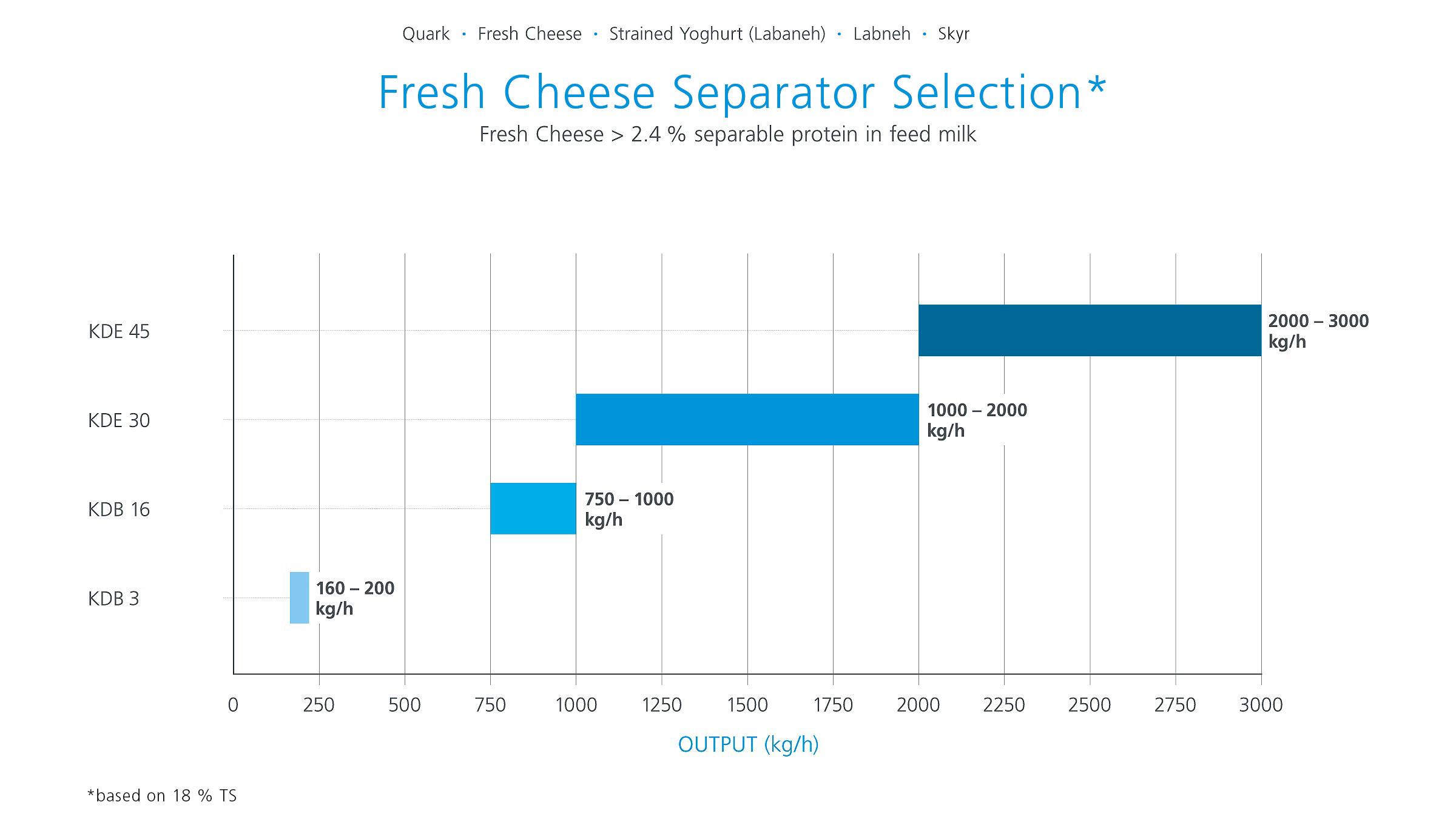

GEA nozzle separators are used in the production of

- Quark (standard or Thermo Quark process, from buttermilk, from recombined milk)

- Fresh cheese

- Strained yoghurt (Labaneh)

- Labneh

- Greek yoghurt

- Skyr

Machine Portfolio

The machines are suitable for fully automatic cleaning-in-place (CIP). To ensure an optimum product quality, a sterile air flow is applied to the hood spaceand the main product-contacting parts are cooled with ice water to support a smooth product discharge. All of the machines are driven by a frequency-controlled 3-phase AC motor.

The product is fed into the machine via a closed system. The whey is discharged under pressure via a centripetal pump and the fresh cheese is released via the nozzles to a solids catcher and floats further down to the cheese hopper.

Related videos

Let's stay in touch!

Contact us