Calculate your extra profit!

GEA STANDOMAT STANDARDIZATION UNIT FOR CREAM FAT OR MILK FAT

Control system

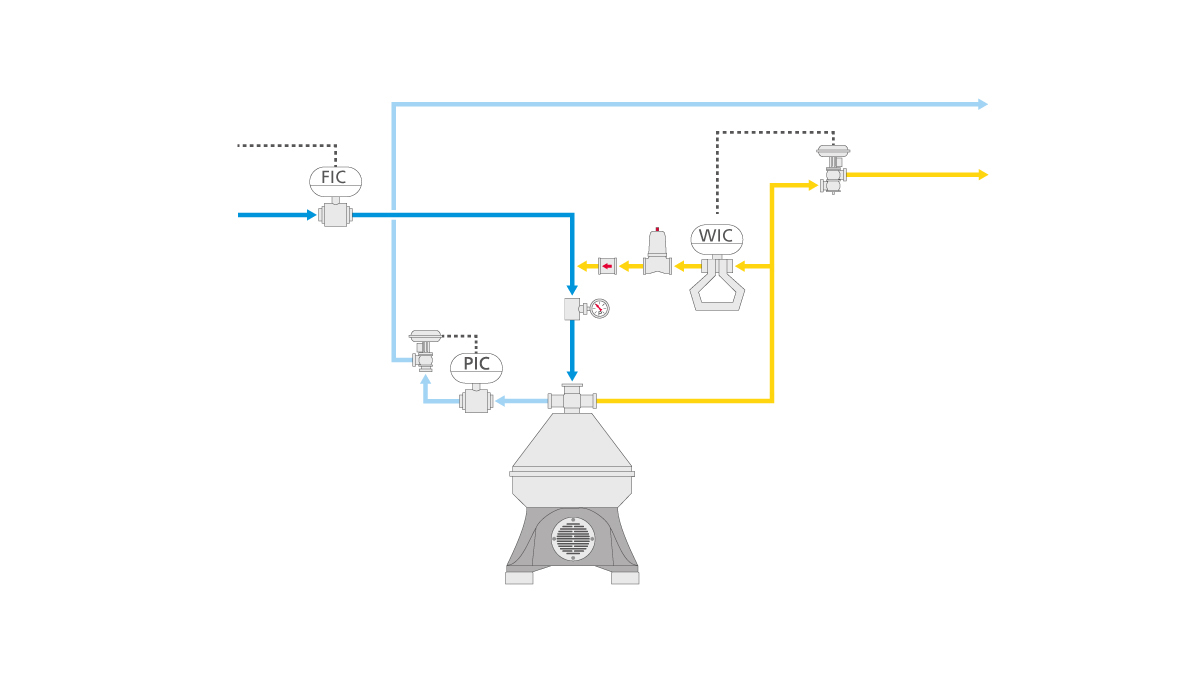

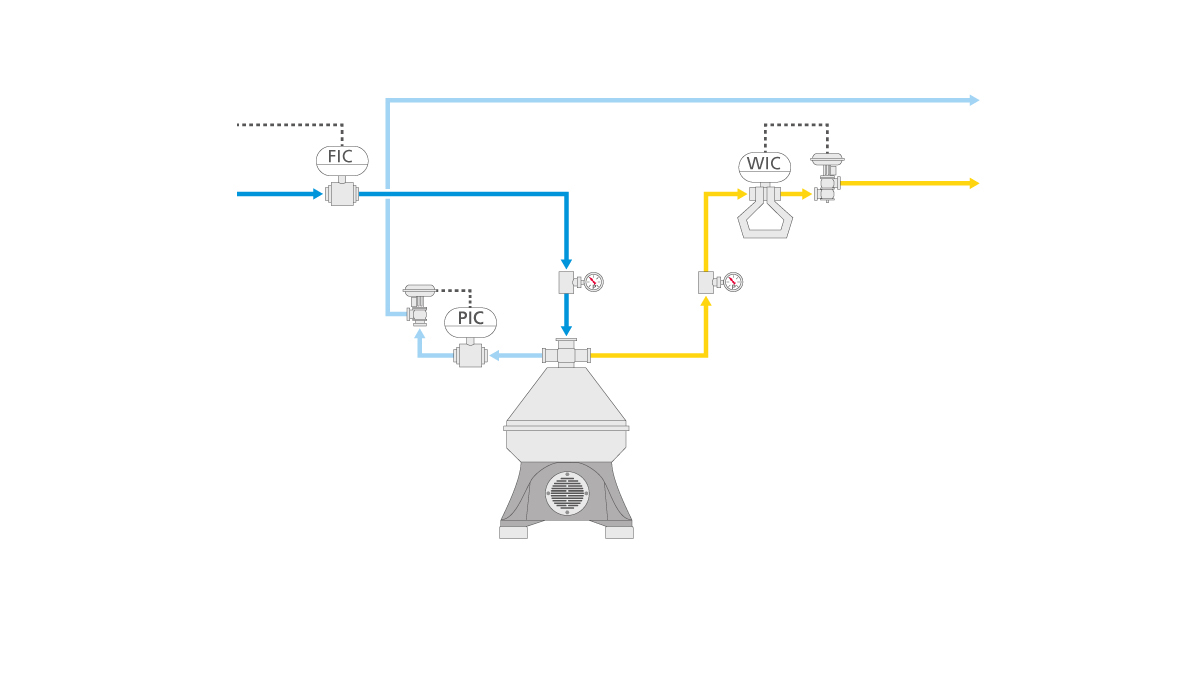

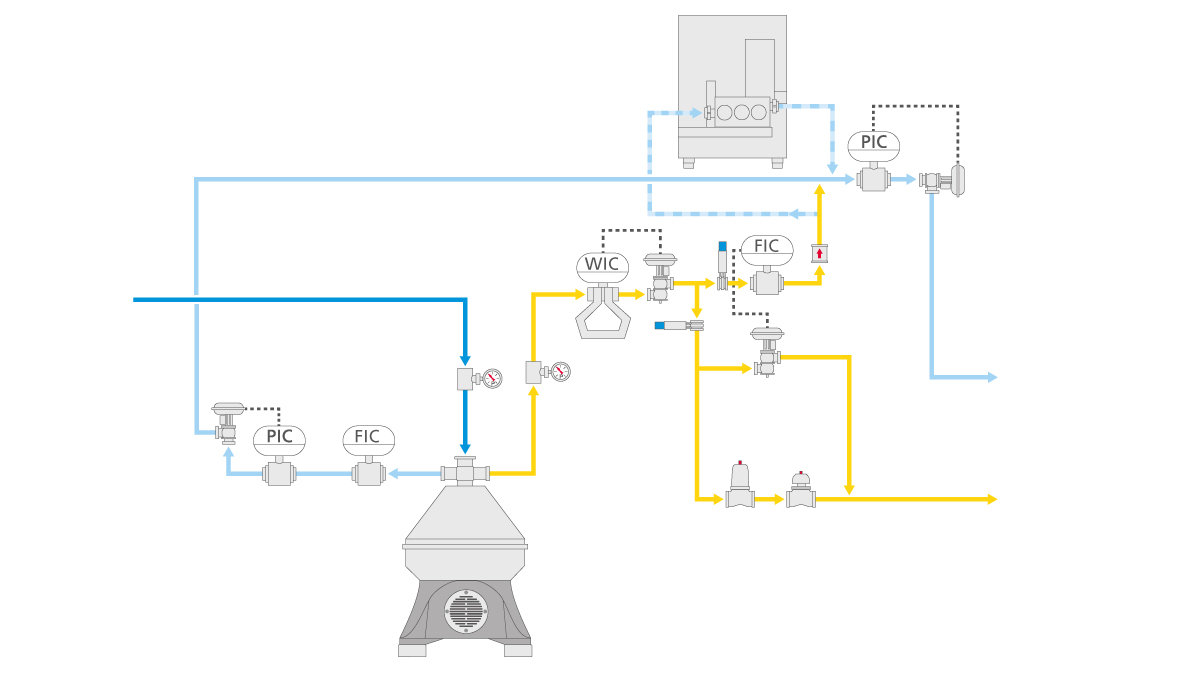

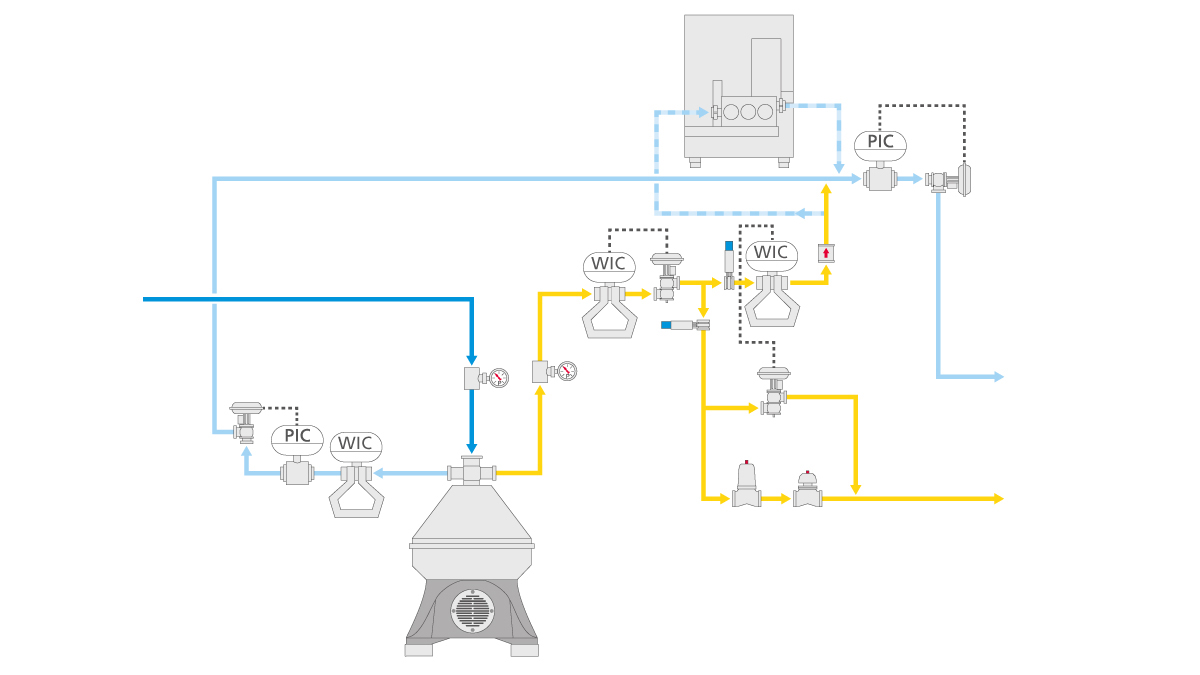

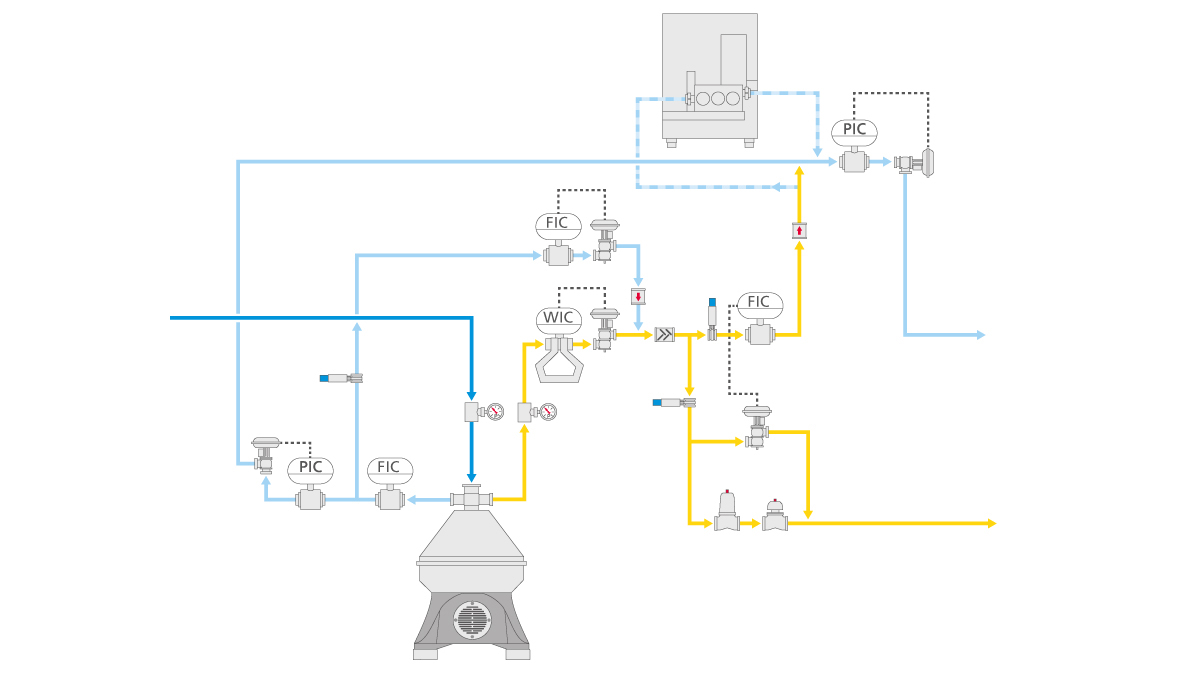

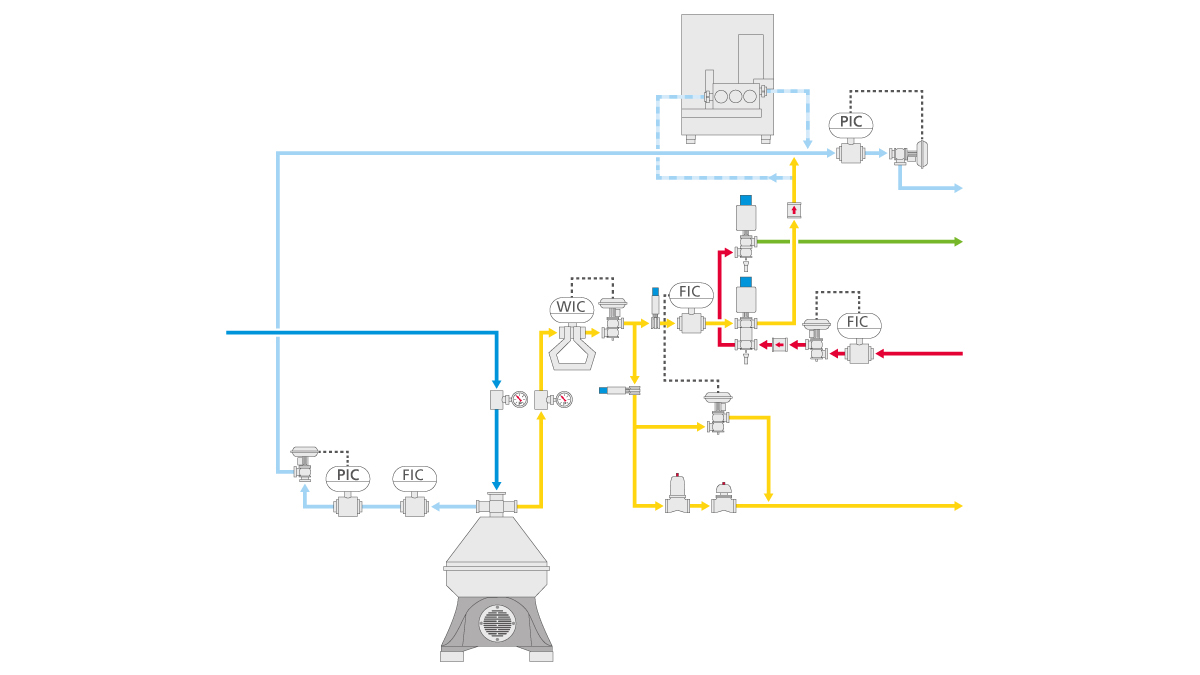

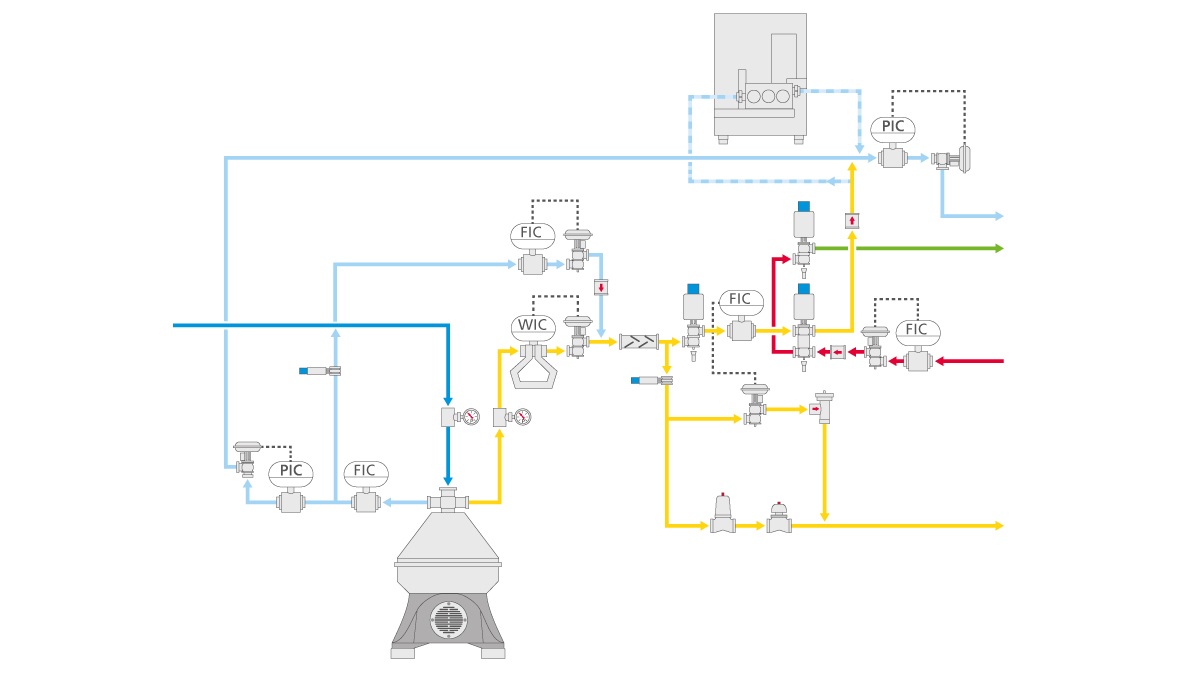

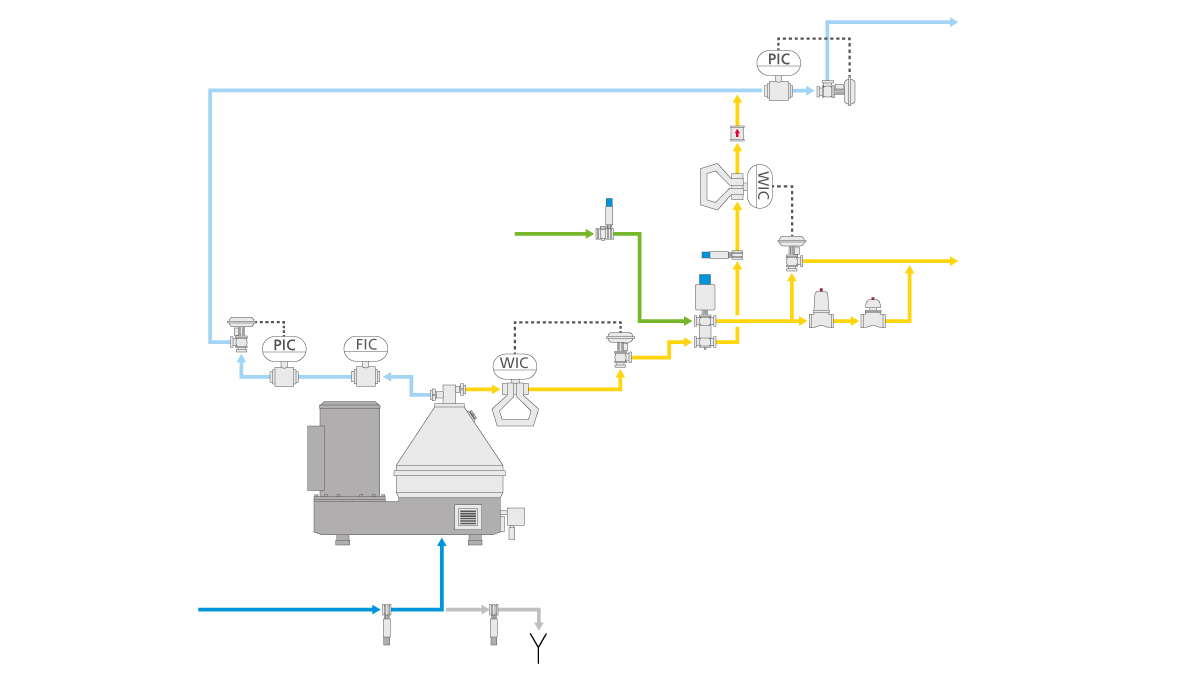

With all models the cream fat content is determined via density measurement in a mass flow meter. The cream fat control is effected by variation of the cream flow. Control procedures adapted to the different operating conditions (start up, production, bowl discharge, shut down) take into account the specific requirements of the separator.

How does it work?

For standardizing, a part of the cream flow is controlled via a mass-flow meter and dosed back into the skim milk. The control components for the skim milk backpressure are integrated on the GEA standomat base unit. For all milk applications the feed flow to the separator is fully controlled and monitored.

What is standardizing?

If milk with a defined fat content is to be produced instead of skim milk a certain part of the cream has to be dosed back into the skim milk. This procedure is called standardizing. Besides the control of the cream or milk fat content, the units can also provide a proportional dosing of additives. Skimming separators split the incoming whole milk into skim milk and cream.

GEA standomat standardization unit for milk and whey

Our portfolio

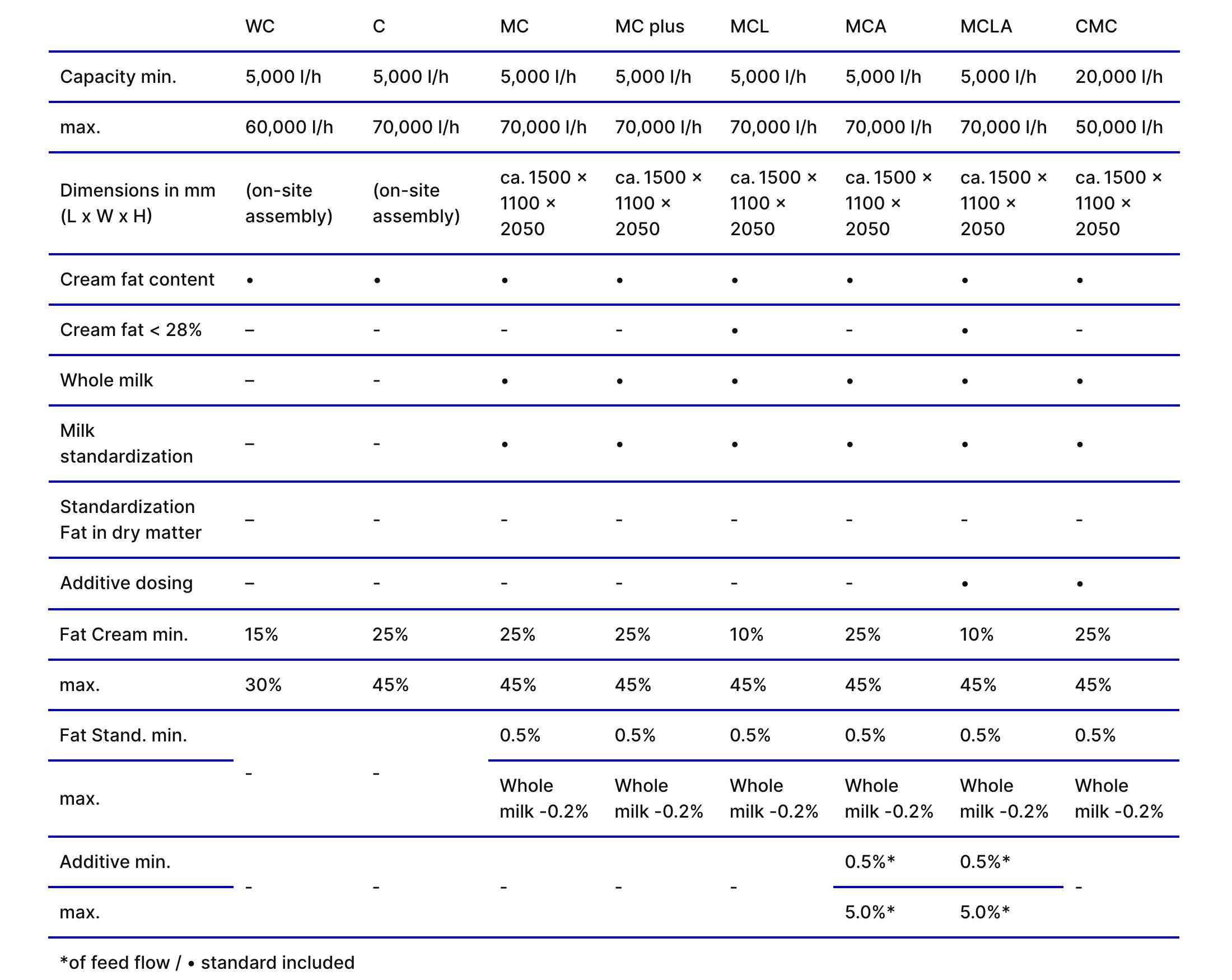

Depending on the application and the control task our customers can choose amongst different standomat models:

- standomat WC

fat control for whey cream - standomat C

fat control for cream - standomat MC fat control for cream + fat control for milk

- standomat MC plus fat control for cream + fat control for milk

- standomat MCL

fat control for cream + low fat cream < 28 % + fat control for milk - standomat MCA

fat control for cream + fat control for milk + additive dosing - standomat MCLA

fat content regulation cream (also < 28 %) + fat content regulation milk + additive dosing - standomat CMC

fat content regulation cream + fat content regulation milk

The above-named versions describe only some of the possibilities available. For individual applications, GEA offers solutions customized to the needs of the customer.

GEA standomat WC

This model is specially designed for the control of whey cream. The cross sections are adapted to the very small cream flow in whey skimming. A partial recirculation of the cream to the feed flow reduces the response time and enables a quick reaction on varying feed flow rates and fluctuating raw whey fat contents.

GEA standomat C

Provides a precise control of the cream fat content at varying feed flow rates. The production is limited to cream and skim milk.

GEA standomat MC

Designed for cream fat control and standardization. It produces cream, skim milk, standardized milk and whole milk.

GEA standomat MC plus

Developped for cream fat control and standardization. It produces cream, skim milk, standardized milk and whole milk at an outstanding level of accuracy. In combination with the latest generation of GEA IO, which ensures a safe and reliable operation to maximize the centrifuge’s performance and availability, an improved calibration makes the process of standardization much more precise and tolerance insensitive.

GEA standomat MCL

In addition to the features of the GEA standomat MC this model allows the production of low fat cream < 28 %, e. g. 10 % coffee cream. This unit enables the production of cream, low fat cream, skim milk, standardized milk and whole milk.

GEA standomat MCA

In addition to the GEA standomat MC the dosing of one additional liquid component like cream, protein concentrate, lactose concentrate or vitamin solution is included. This allows the production of cream, enriched skim milk, enriched standardized milk and enriched whole milk.

GEA standomat MCLA

This version is based on the MCL model. Additionally, dosing in the corresponding ratio and complete admixing of additional components can be realized.

GEA standomat CMC

In the cold milk process, this model additionally regulates the fat content of the milk (standardization). By this means, cream, skim milk, standardized milk and whole milk can be produced.

Technical Data GEA standomat

Milk standardization process

Procedure with warm milk

A high performance of the control system requires a stationary operation of the system at steady process conditions. The system is calibrated according to laboratory tests, which can be done by different analytical methods. Thus, any verification has to be carried out using the same methods. The accuracy of these different methods has to be taken into consideration while interpreting results.

The maximum fat content for standardizing is 0.2 % below the incoming whole milk fat content. The deviation from the setpoint for cream fat control is +/- 0.2 %. For milk standardizing, this deviation is on-line 0.05 % right after the control unit and 0.025 % after a buffer tank.

Procedure with cold milk

Cold milk standardization in particular makes possible a fat content in the milk of 0.5 – 4.2 %, whereby the raw milk content should be at least 0.2 % above the standardized milk fat content. The standard deviation is around +/- 0.04 %. The cream can be standardized up to maximum 40 % fat content. The control deviation here is +/- 0.4 %.

Partial homogenizing

The models MC, MCL and MCA can be prepared for partial homogenizing of the standardized or whole milk. With this a good homogenizing effect can be achieved with a homogenizer of 1/3 of the total capacity.

Cleaning

The automatic cleaning of the GEA standomat is effected by the CIP of the separator. Optionally the connecting valves for a separate CIP of the surplus cream line can be integrated into the unit. The additive dosing line of the standomat MCA is cleaned in a separate cycle in any case.

Compact unit

The models WC and C do not require a rack, the individual components have to be mounted on site into the separator connection lines. The models MC, MCL and MCA are preassembled as a compact unit in a stainless steel rack. The control cabinet and the solenoid box are mounted on the rack. All internal electrical and pneumatic connections are installed. Each unit is tested before dispatch.

Controls

GEA IO is the new control panel generation for all GEA separator and decanter applications, focusing on intuitive handling, efficient processes and reliable operation.

Control functions

Logical navigation without redundant information enables user-friendly operation and safe monitoring of all centrifuge functions. GEA IO can be operated as an individual controller or via optional bus communication.

Machine supervision

All required data are continuously monitored and evaluated in the background by the system. GEA IO provides reliable information continuously (e.g. speed, temperature, vibration, etc.), enabling the plant operator to take action when required.

Monitoring and control of GEA standomat

All functions required for reliable and accurate standardization such as density measurement, flow measurement, dosing, etc. are monitored and controlled precisily by GEA IO.

GEA IO-assistance

One innovation of the new GEA IO control system is the user guidance facility. Assistance systems focusing on simplicity and usability are integrated or are optionally available.

Related videos

Let's stay in touch!

Contact us