GEA milk Pasteurizer

GEA MILK PASTEURIZER

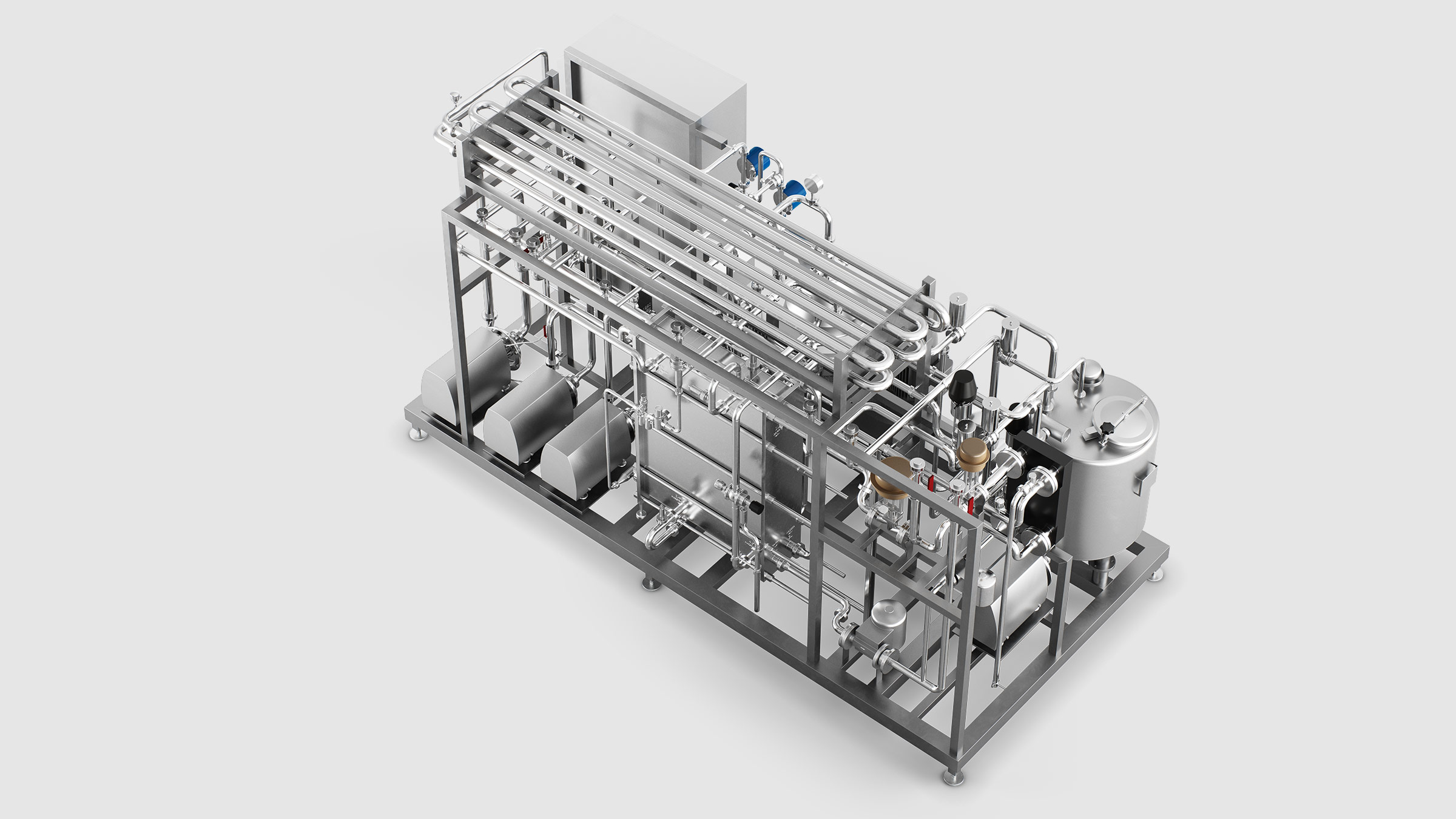

Compact and pre-assembled milk pasteurizer with a skimming centrifuge

The GEA milk pasteurizer is the right choice if you …

- … are looking for a partner capable of supplying a complete pasteurization line.

- … need to get back on production quickly and don’t have time for on-site installation and a lengthy commissioning time.

- … require a flexible solution which provides easy processing of raw milk and cream.

- … prefer an easy-to-use system that supports the operator in optimizing the output.

Product passport

- Available for capacities from 3,000 to 10,000 l/h:

– GEA milk Pasteurizer 3000

– GEA milk Pasteurizer 5000

– GEA milk Pasteurizer 10000

- Available skimming centrifuges:

– GEA milk Skimmer pro 20

– GEA milk Skimmer pro 40

– GEA ecocream

- Completely skid mounted

- Flexible operation:

– Milk

– Cream

- Options:

– Cheese milk

– Yoghurt milk

– Partial homogenization

– Cream cooler

– CIP dosing

Your benefits at a glance

- Compact design of the pasteurizer

– Reduced space requirement

– Easy to operate – optimized yield

– Easy maintenance – less downtime

- Flexible operation

– Capable of processing milk and cream

– With or without separator

- Skid mounted solution

– Easy and fast integration

– Quick commissioning

– No need for opening the floor

- Less coordination effort with third parties

- Easy operation via user-friendly HMI

- IOT ready and remote access option

Available options for customization

- Pressure-priming pump + differential pressure control

– Provides additional process safety

– Additional pumping pressure to reach the final destination tank

- Cream cooler

– Cools the cream down to 8 °C for intermediate storage

- Post heating for cheese milk

– 20 – 45 °C post heating for direct feeding of the cheese vat

- Yogurt milk treatment

– 90 °C increased heating temperature to improve yield

– 6 min holding time as separate stand-alone unit

– 20 – 45 °C post heating for direct feeding of the fermentation tank

- Partial homogenization

– Drinking milk to prevent cream separation

– Yoghurt milk for better structure

- Lost CIP

– CIP dosing system for caustic and acid concentrates

- Anybus gateway for signal exchange

- mGuard for remote access

Design features

- All components are installed and connected

- Everything is tested in the factory

- Quick installation on site

- Minimal installation effort

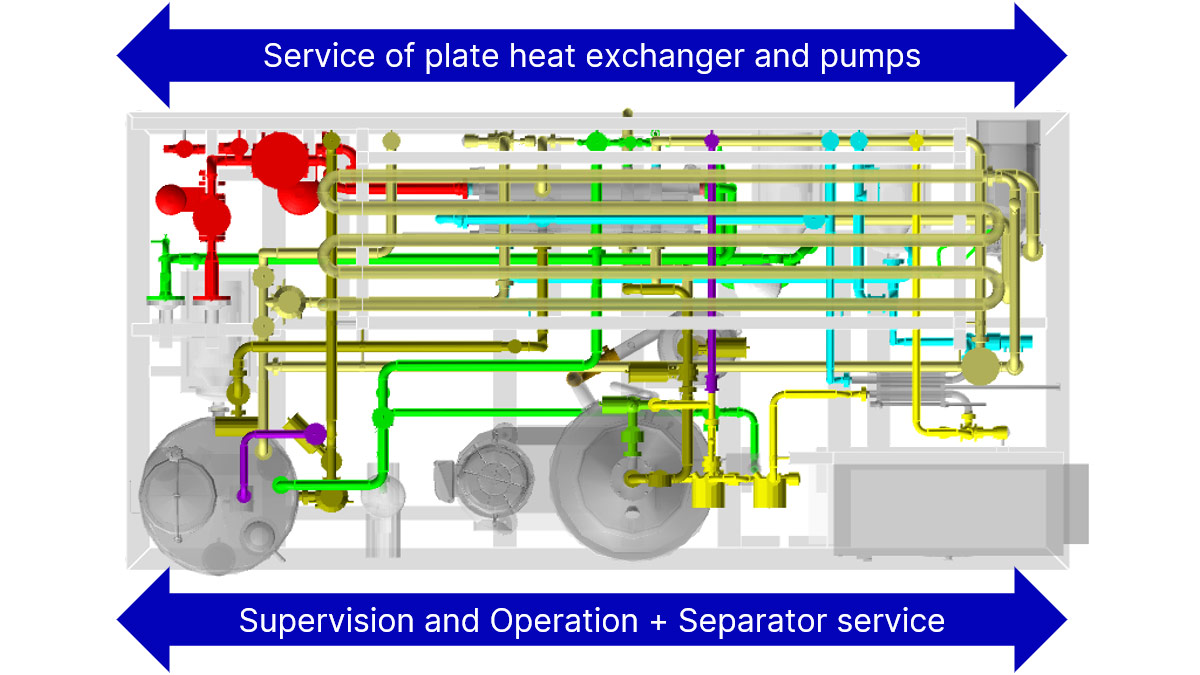

- Compact design supports the operator – easy operation

- Easy relocation

- Easy to maintain due to special attention of space requirements for dismantling the equipment

Centrifuge features

- Optimally integrated into the process

- Pasteurizer and separator are set up to provide the following:

– Optimal process condition for optimal skimming performance

– Optimized CIP process to save time

– Possibility to operate the pasteurizer alone

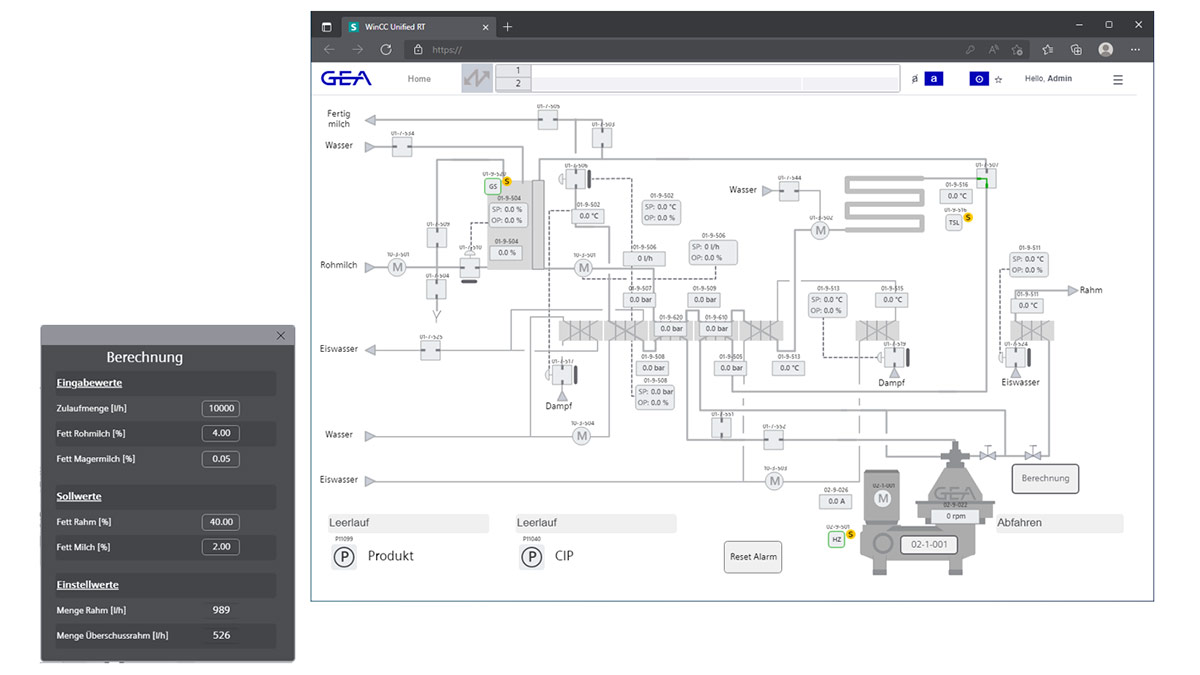

Automation features: New user-friendly HMI

- Complete process in one window

- Easy overview of process data

- Operation in automatic and manual mode possible

- Trending possibility of different parameters

- Standardization calculator to support the operator to setup the flows correctly

- IOT ready

Related videos

Let's stay in touch!

Learn more about innovations and our products, by signing up to our newsletter.

Contact us

We are here to help! With just a few details we will be able to respond to your inquiry.