GEA CODEX® TRACEABILITY

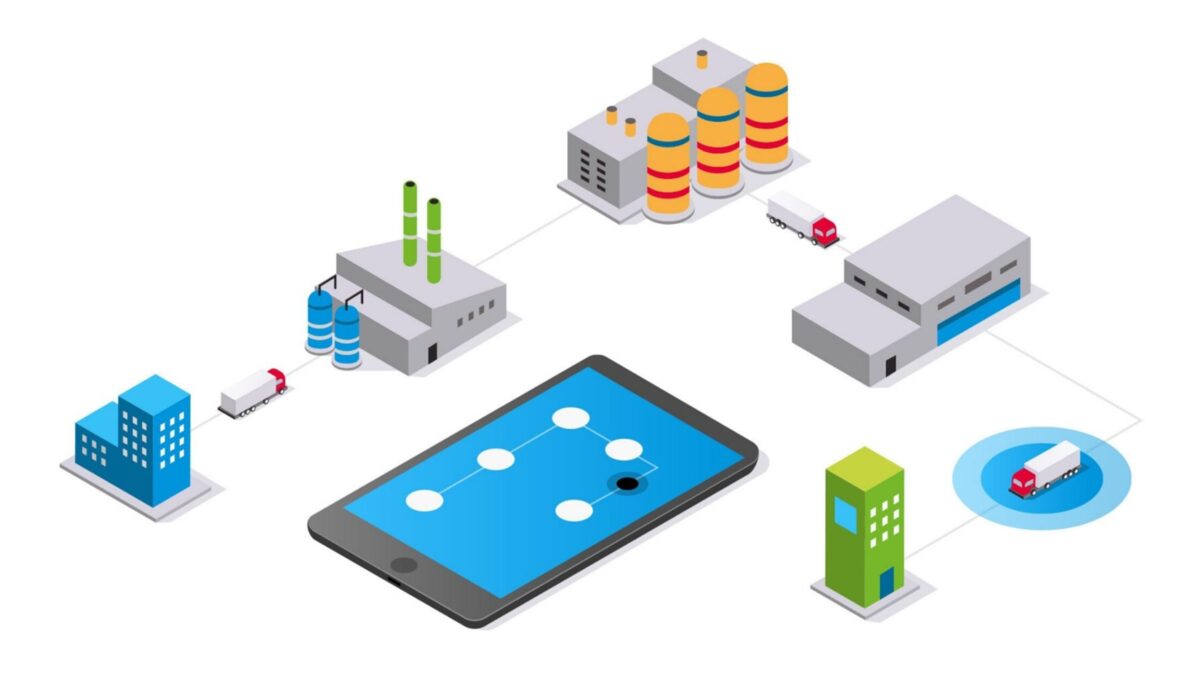

GEA Codex® Traceability is a software product that records the transfer of material lot numbers and quantities from goods received to finished product. A user-friendly graphical interface provides an intuitive overview of the manufacturing facility that highlights the equipment used for the selected production run. In an industry in which traceability requirements are nothing new, growing consumer pressure is driving companies to further increase manufacturing execution transparency.

Recognize your benefits:

- Record every step of your process and monitor materials during use

- Track batches, serial numbers, additional process values and acquired measurement data

- Reduce production variability, prevent out-of-specification product and subsequent recalls

- Specify ingredient usage via tracked searches

- Stay compliant with standards and specifications

- Save time with combined trace reports

- Optimize utilization

In addition, tracking forwards and backwards, from any part of the process, allows for more detailed analyses of batch genealogy. Plus, paperless tracking increases product quality, consistency and satisfies regulatory requirements and audit reports.

GEA Codex® Traceability’s graphical interface lets you drill down from plant overview information to any single product movement. With a small footprint, this application-focused software offers user-designed screens of the production areas and is scalable from R&D level to commercial production.

Both manually acquired and automatically generated supply data ensure that even complex, multi-pass processes can be tracked and logged. It enables users to track every single transformation step or product movement — both forward and backward, from raw material to final product — to facilitate process optimization in terms of cost and efficiency.

Together with GEA Codex® Connect, GEA Codex® Traceability integrates with existing ERP platforms to track both order and recipe parameters, as well as production phases or events, and delivers results to employees from the shop floor to control, procurement and beyond. Recorded data can subsequently be exported for advanced analysis if required.

Furthermore, historical traceability and alarm-related records can be used to enhance the overall view for better analysis and review. Easy to use, the software is a valuable product safety tool. It helps with regulatory compliance, provides a simple way to support audits and provides a high level of customer care and confidence.