Overview

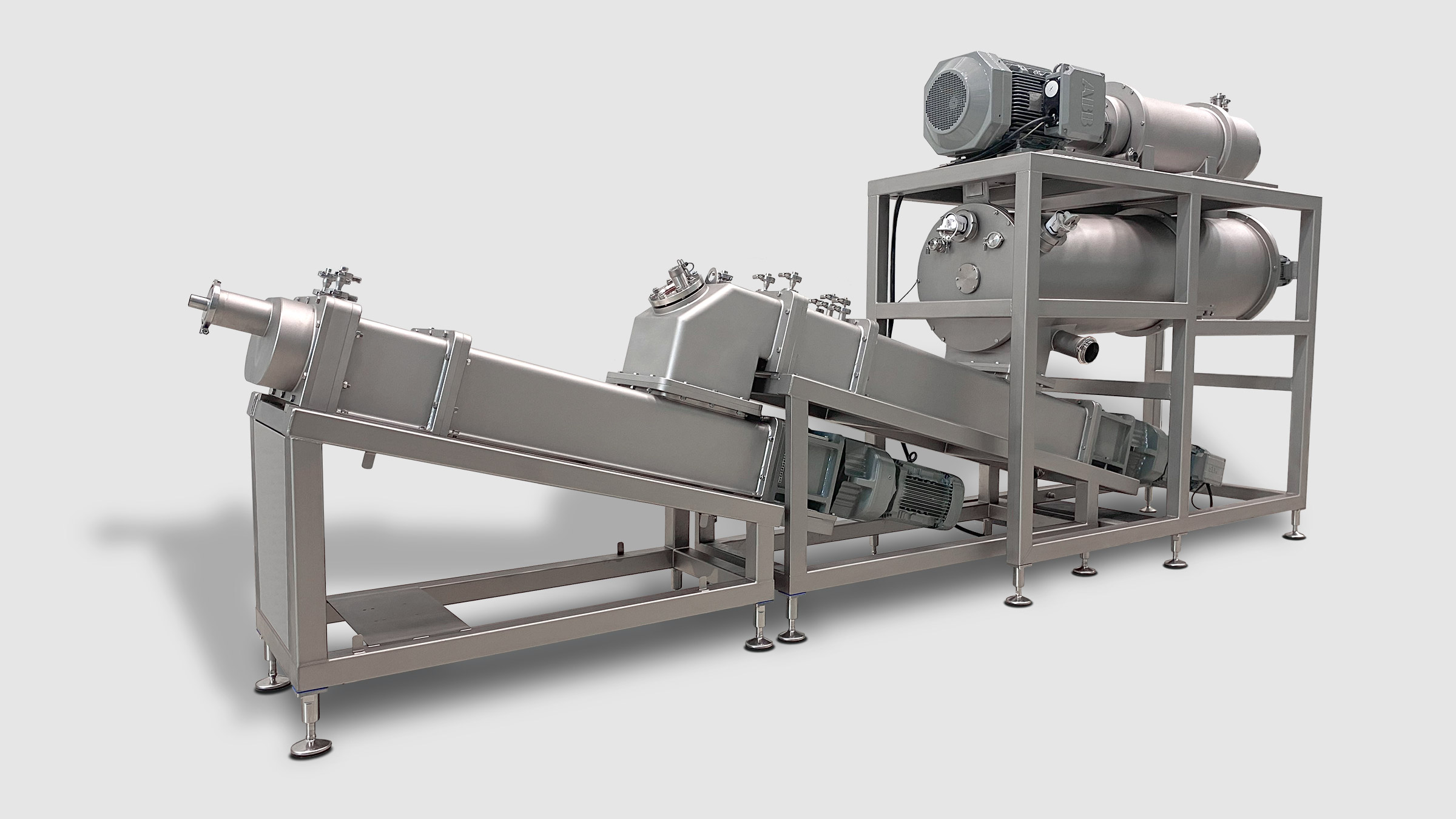

GEA BUTTER MAKER

With an expected annual growth rate of about 3% until 2026, butter production capacities grow significantly faster than those of many other dairy products. And attraction is rising: While table butter is primarily associated with Western cuisines, its relevance for Asian eating habits is increasing, while traditional milk fat products such as white butter and ghee enjoy unimpaired popularity. The particular demand of small and specialized butter manufacturer’s for highly flexible, robust and economical solutions is answered by the new GEA butter Maker 1000.

Features & highlights at a glance

- 800 – 1,800 kg/h butter production capacity for small scale dairies

- Open stainless steel frame for easy access to all relevant parts for cleaning and maintenance purposes

- Large churning cylinder surface for less sieve blockages and longer operating times

- Modular configuration of texturizers depending on target milk fat products for precise process adaption

- Compact design for lower installation efforts

- Optimized design for superior cleanability and product safety

- Various lighted sight glasses for close process monitoring and control

- Optional remote monitoring via camera system

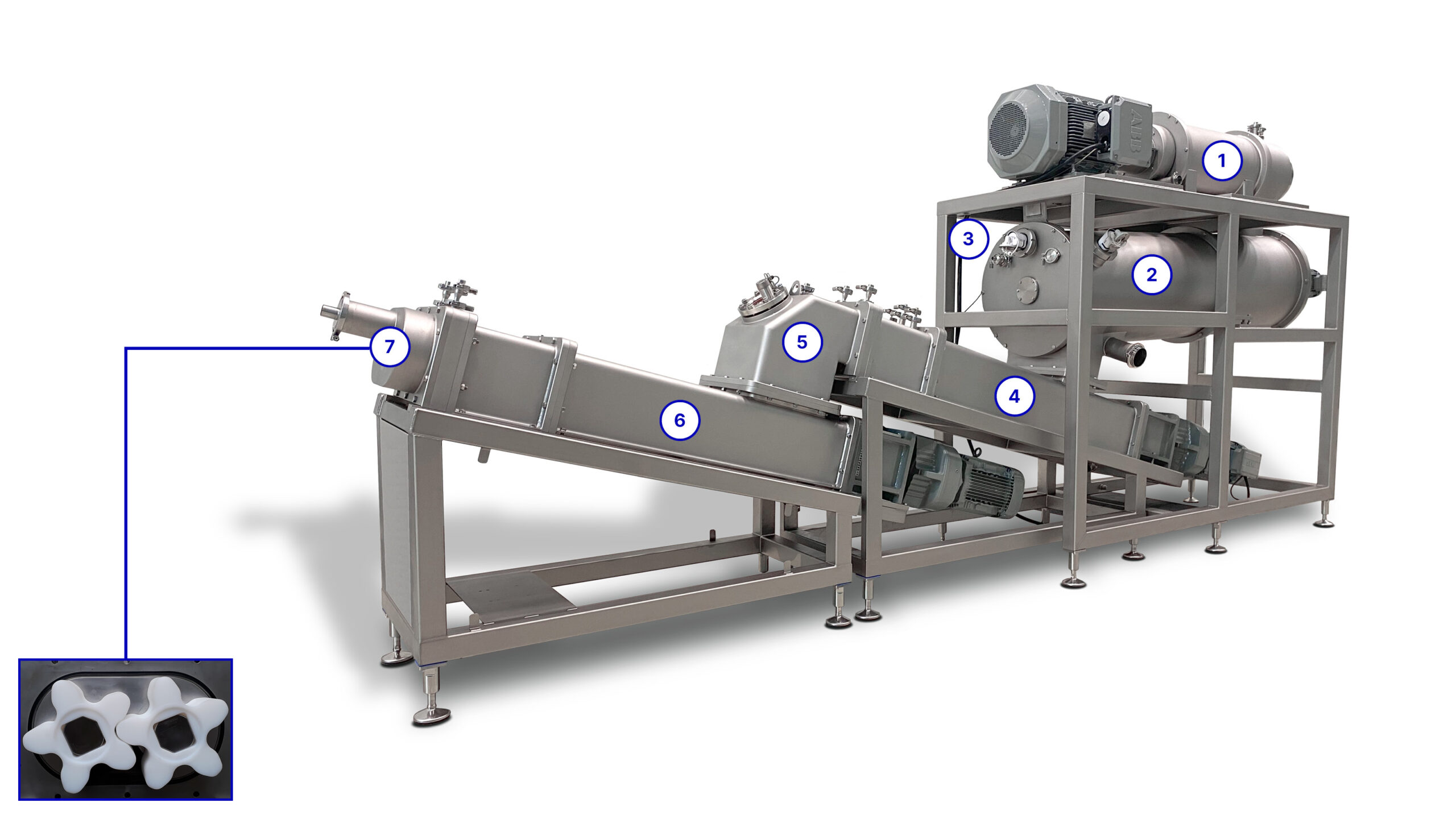

1 Primary churning cylinder

2 Secondary churning cylinder

3 Camera system

4 Primary texturizer

5 Vacuum chamber

6 Secondary texturizer

7 Integrated butter pump

The GEA butter maker is the perfect choice, if…

- you need a flexible design for various butter styles, such as table butter, white butter or butter for ghee

- you focus is on having a complete process line solution of modular design for quick and trouble-free installation

- an economic solution is key and basic features are sufficient for your success

- you don’t want to waive the premium service and support you may expect for all GEA products

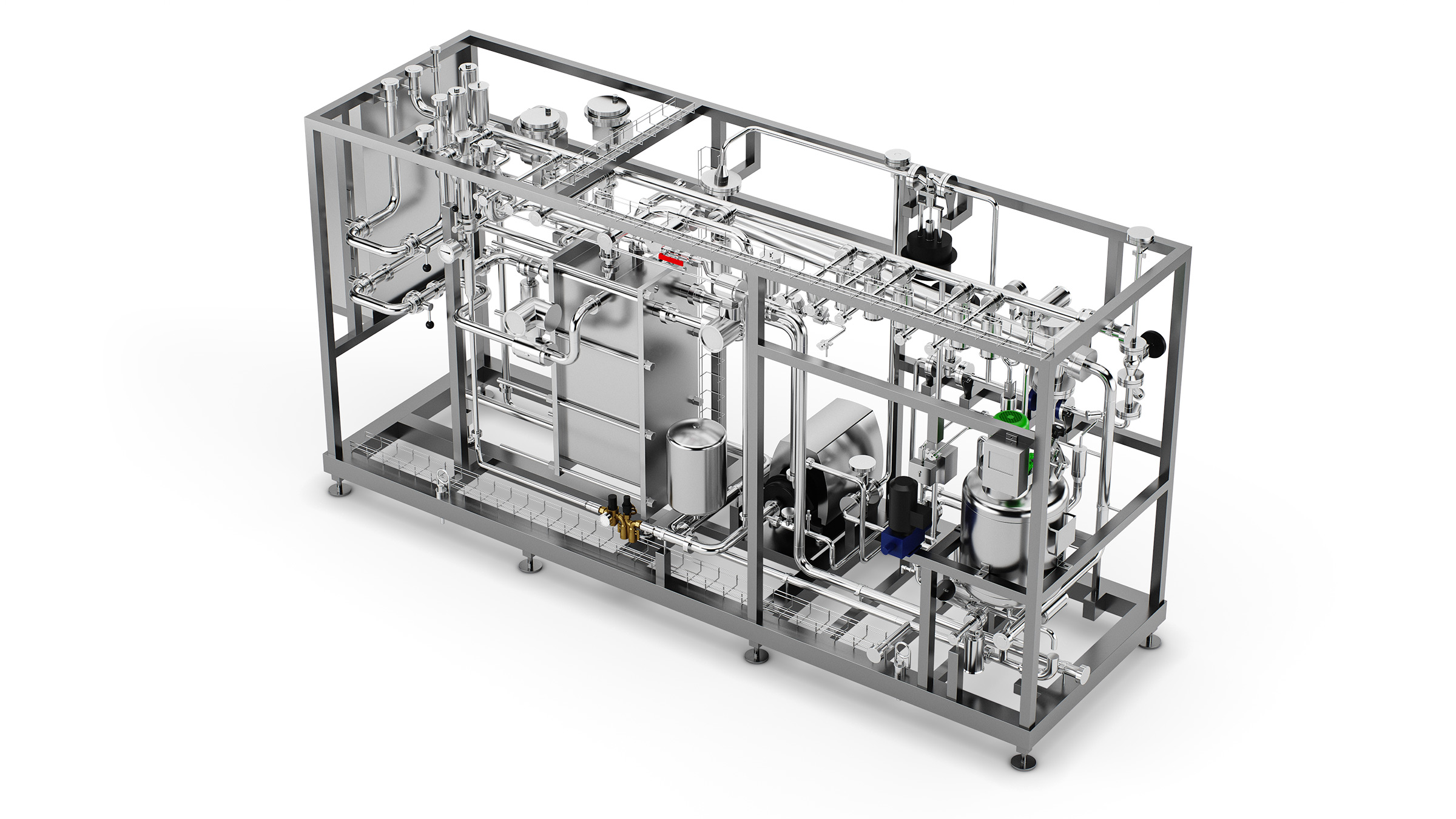

Turnkey is not luxury – it’s smart

For all dairies looking for a quick and hassle-free installation and startup, there is a complete skid including cream pre-heating, ingredient dosing, CIP supply and buttermilk collection and cooling available. This convenient solution is not only attractive for new green field plants but facilitates a smooth replacement of existing equipment as well. Furthermore, GEA specialists master the entire value chain, from raw milk reception to the final butter and will ensure that the desired butter specification will be met. Because being up and running quickly for production is not a luxury, it’s smart.

Let's stay in touch!

Contact us