CLARIFYING DECANTERS FOR CHEESE CURD, CASEIN AND LACTOSE

The decanters ensure the efficient production of processed cheese base, raw goods for curd cheese bars or bakers cheese. The decanters are also ideally suited for reprocessing cheese fines and for lactose and casein production thanks to their design, which has been optimized for the production of delicate foods.

Outstanding efficiency

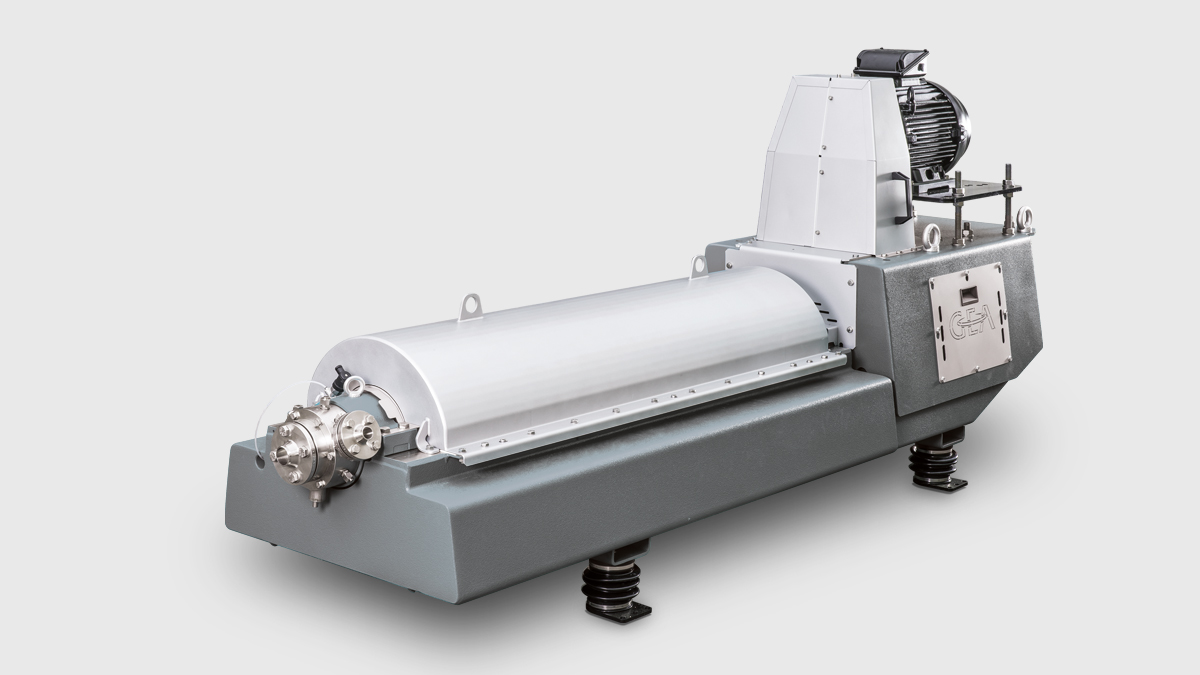

The latest GEA decanters, the ecoforce series, impress with top performance, which is achieved with an adapted bowl speed, combined with a low energy consumption. The high-torque GEA summationdrive reliably provides the optimal differential speed, which guarantees the best possible operation. Only the power that is actually required is supplied to the motors, which means that the drive works extremely energy efficiently.

Simple maintenance

GEA gearboxes for GEA decanters: The gearboxes for the ecoforce series are manufactured in our in-house production facilities because of the need to adapt them optimally to the respective decanter design configuration. In total, seven gearbox sizes are available for integration in the series along with three gearbox types classified by decanter size and model. The decanters have been consistently designed for continuous operation and maximum availability. The gearbox has therefore been taken out of the product space and placed outside. This makes it not only less easily affected by product temperature but also very quickly accessible for the service technician. This applies for all areas of the decanter that require regular maintenance, so the machine is quickly ready for use again.

Decanter series in hygienic design

The GEA ecoforce decanters can be offered with different levels of hygienic design to ensure an exceptionally high product and process safety for microbially sensitive products. This special design guarantees the user processing and production of foodstuffs at the highest level, in a way that is hygienic and reproducible and which guarantees the consumer comprehensive process and thus product safety through complete CIP-ability and reproducible cleaning.

Hygienic design in accordance with customer requirements

A specification sheet was created in close cooperation with customers and in consultation with a hygiene consultant, which was used as a basis for food-technology-compliant design. Leading customers in the dairy industry have therefore already chosen this new decanter technology for producing casein and lactose, for example.

Hygienic decanter technology fulfils individual customer requirements

We can offer different hygiene standard levels depending on the hygiene requirements of the customer. Customers can choose between the “Standard”; “Comfort” and “Advanced” versions in accordance with the individual requirement profile of the product. “Advanced“ versions offer hygienic design in accordance with EHEDG and 3A guidelines.

These versions differ in the following aspects:

- Grooves not used for product transportation

- Welded or screwed spray nozzles

- Aseptic or standard flange

- Surface finish of the parts in contact with the product

- Type of feed system (hermetic or open)

- Sealing of grooves, gaps and screw heads

- Paint (textured or smooth lacquer)

The rotor impresses by the fact that grooves do not need to be used and the surface of the parts in contact with the product and CIP has a roughness of Ra < 0.8 µm in the highest hygienic decanter standard

Other customers from the food industry can now benefit from the references for the dairy decanters from the GEA ecoforce series in use in some European dairies and choose a decanter which is optimally designed for their specific hygienic requirements.

Scroll

- Smooth surfaces (Ra 0.8µm)

- Hermetic scroll body with other „advanced“ design features

Solids discharge

- Optimized solids discharge port design

- No possibilities for product residues

Hood

Defined spray nozzles arrangement

Spray nozzles

- Weld-on

- Optimized spray cycles sequence

Hermetic feed system

- Rotating feed tube and box distributor

- Soft product acceleration

- Defined CIP guidance

Bowl shell

- Smooth surfaces

- Increased CIP-ability

Technical Features & Capacities

Both decanter designs correspond to the requirements of a fully CIP-able machine. Both of them can optionally be supplied with the GEA condition monitoring system for continuous monitoring of the machines as a basis for targeted pro-active maintenance.

Capacities

Type MCE:

- Cheese fines: 2000 – 4000 l/h

- Cheese applications: 2000 – 6000 l/h

- Casein applications: 2000 – 6000 l/h

- Lactose: 500 – 3000 kg/h

Type ecoforce:

- Cheese fines: 2000 – 6000 l/h

- Cheese applications: 3000 – 45,000 l/h

- Casein applications: 2000 – 60,000 l/h

- Lactose: 1000 – 15,000 kg/h

Options

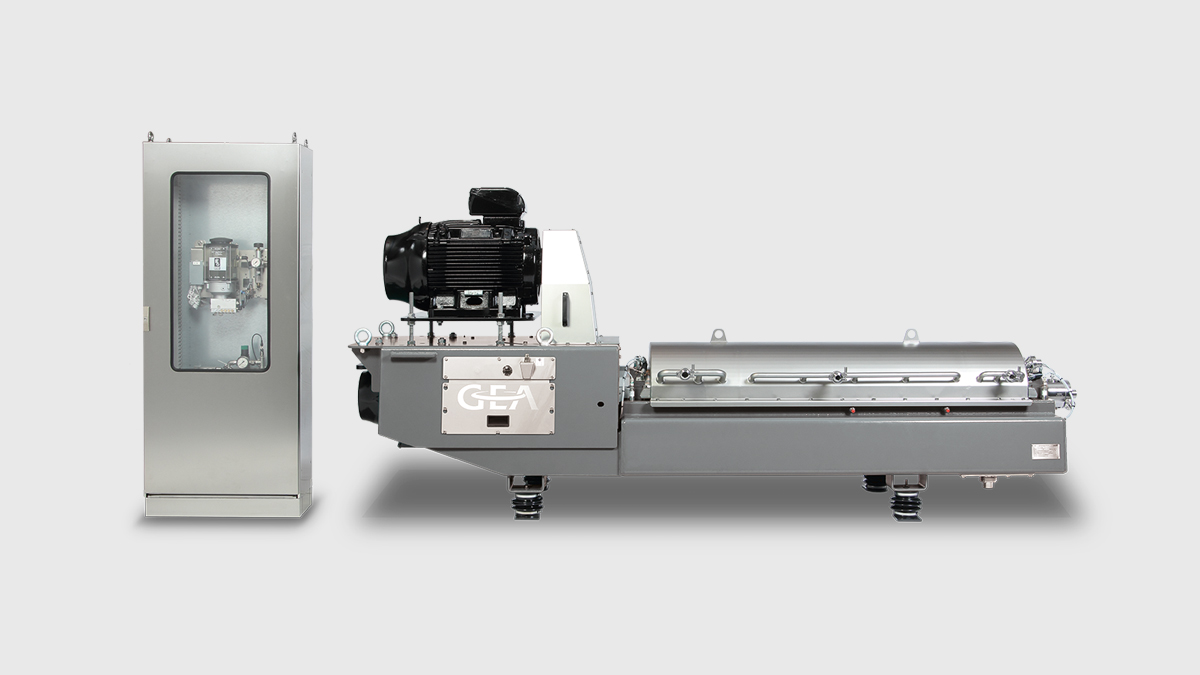

Type MCE:

- Feed flow control

- Process control (PLC)

- Motor control (MCC)

- GEA condition monitoring

Type ecoforce:

- Process control (PLC)

- Motor control (MCC)

- Additional process equipment like tanks, valves, pumps and control instruments

- Condition monitoring system for proactive maintenance

- Feed flow control

- Control of backpressure of centripetal pump

- Advanced hygienic design features in accordance with EHEDG and 3-A guidelines

Related videos

Let's stay in touch!

Contact us