Machine automation solutions for GEA separators and decanters

AUTOMATION & CONTROLS SEPARATION

GEA IO – One control for every centrifuge

Next to control and display reliable data, GEA IO is able to capture and evaluate data. GEA IO ensures a safe and reliable operation to maximize the performance and availability of your centrifuge.

Serviceability

Excellent equipment is one thing, the right service is another. GEA supports you throughout the entire life cycle of your installation. Customized Service tools enable a perfect insight into the control to operate your equipment under optimal conditions.

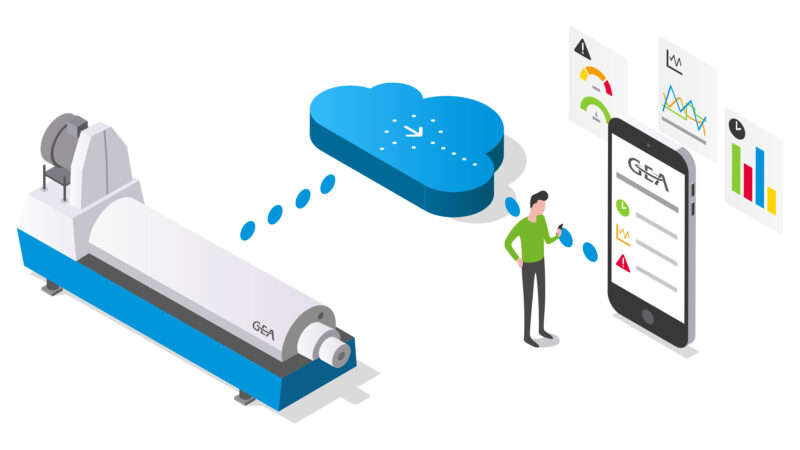

Cloud Monitoring and Trending

GEA IO provides you with complete machine data online. Optional cloud server solutions and customized dashboards show machine status, process data, trends, alarms, etc. Always and everywhere!

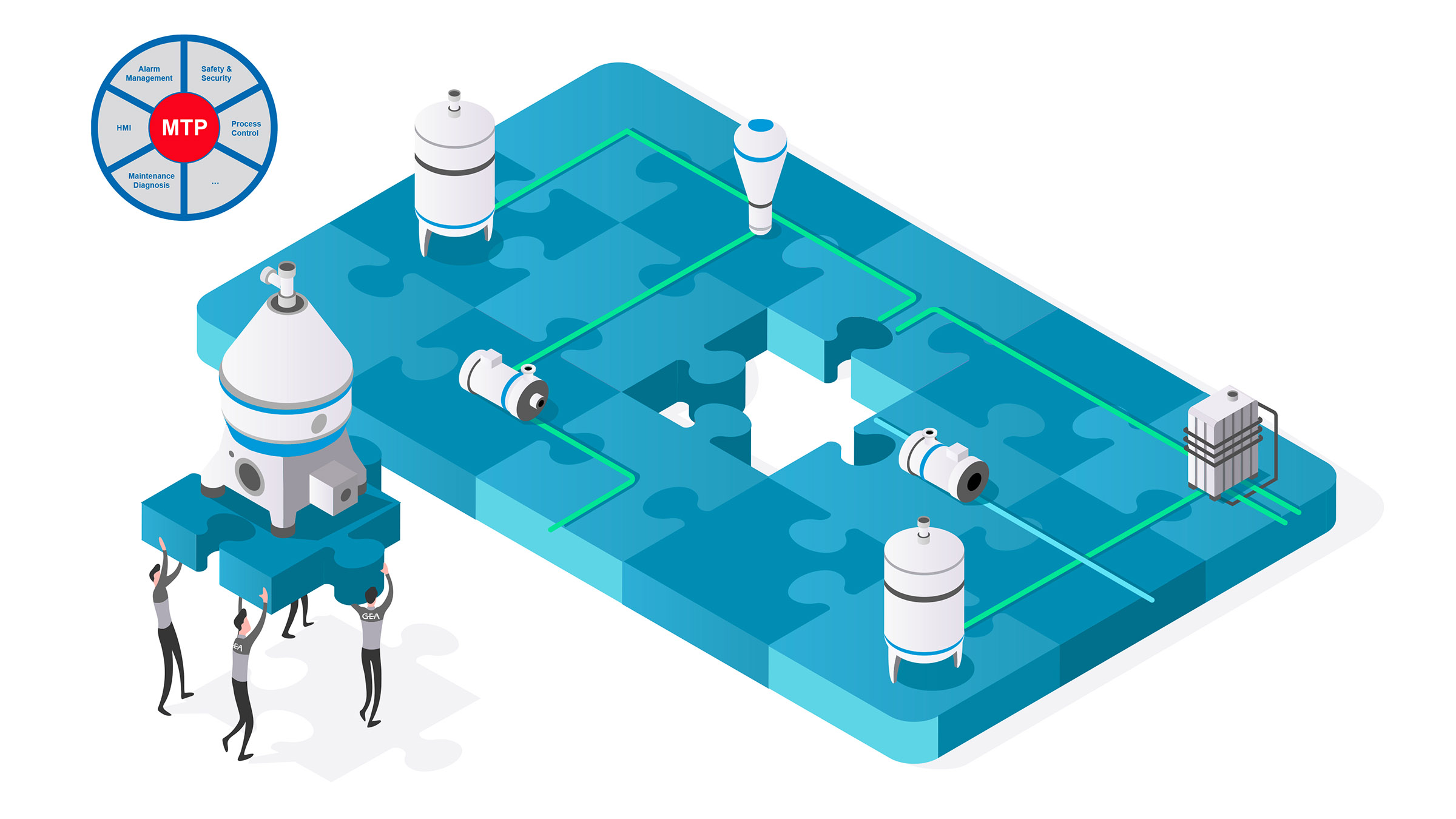

Enhanced connectivity by MTP

Modular and highly flexible production requires modular automation. GEA offers Module Type Packages (MTPs) that contain all the information required for easy implementation in customers’ production lines.

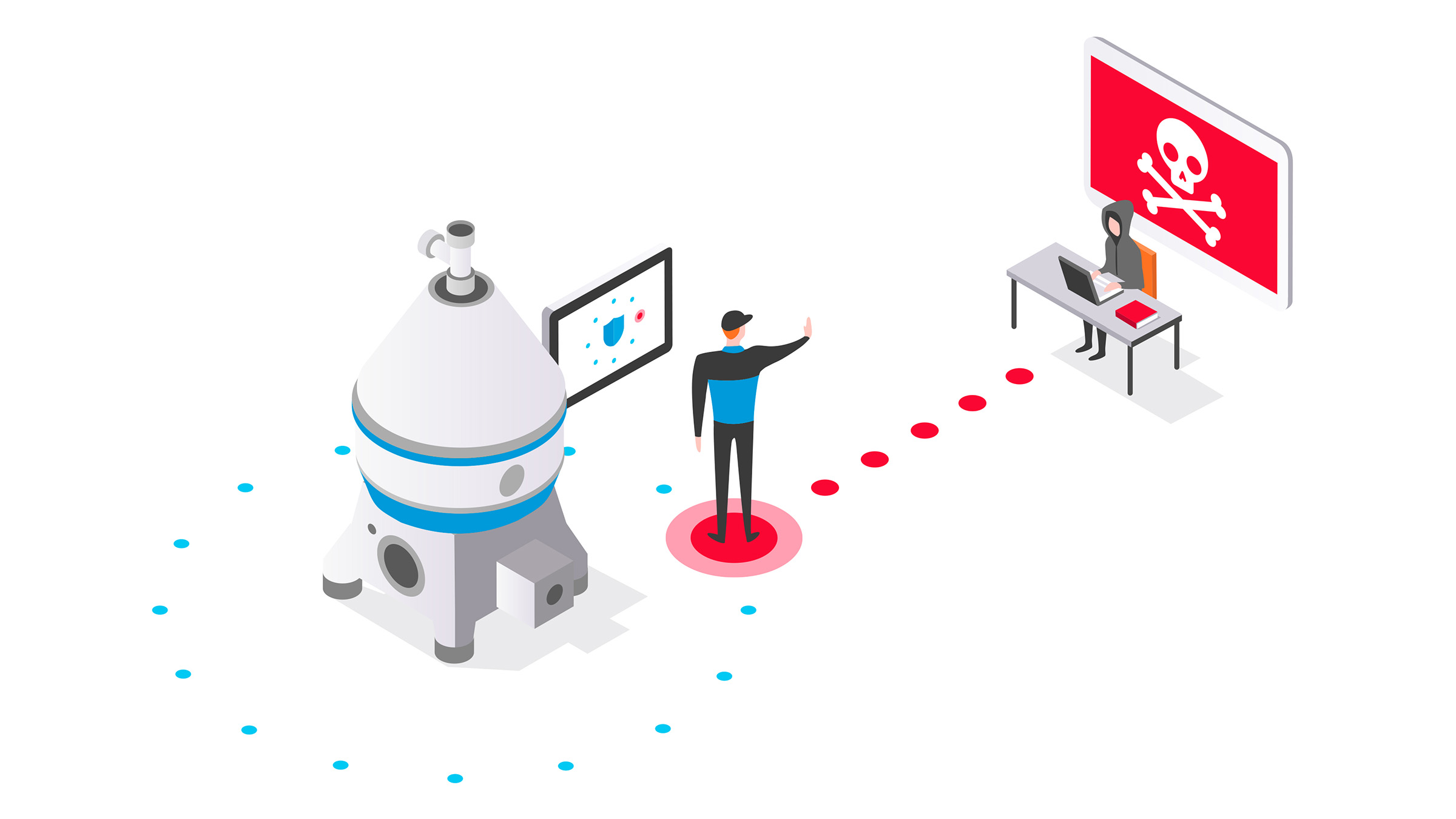

Cyber security

The digitalization of industrial production poses an increasing risk of cyber attacks. Cyber security is a highly sensitive domain in which GEA is your reliable partner.

Software quality

What has been modified is saved. Who did it, why, when and where? Full transparency of the change process during development, testing, acceptance test and commissioning ensures highest software quality.

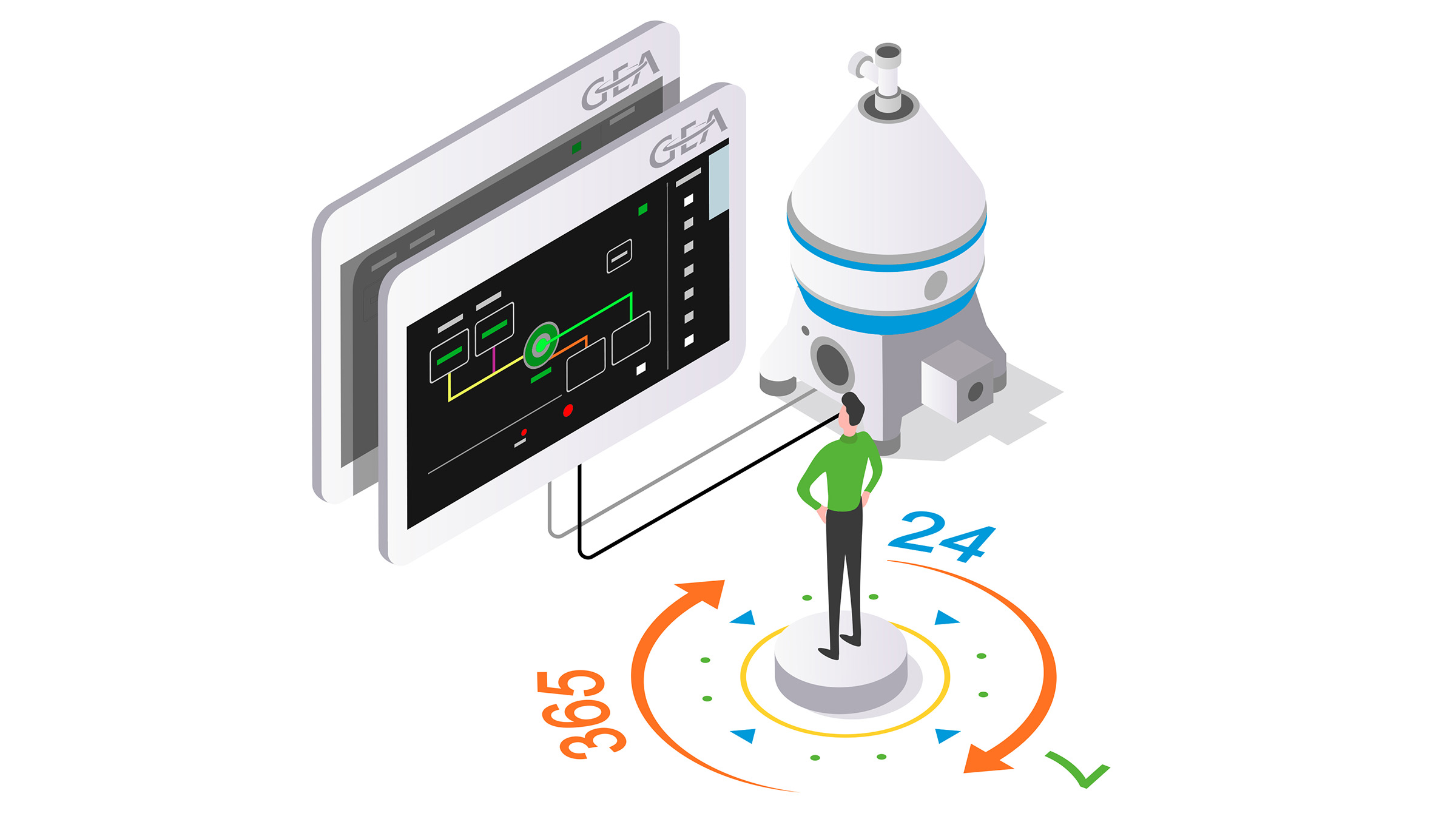

High availability of controls

Industrial applications are facing a continuously increasing degree of automation. As a result, the availability of controls becomes significantly important. GEA covers this with special hardware in hot standby mode. 24 hours a day, 7 days a week, 365 days a year.

Regulations / certifications

The topic of safety plays a crucial role in automation and controls for GEA centrifuges. GEA offers this safety – no matter where and for which application – whether for complex projects for process lines or for supposedly simple tasks on independent machines.

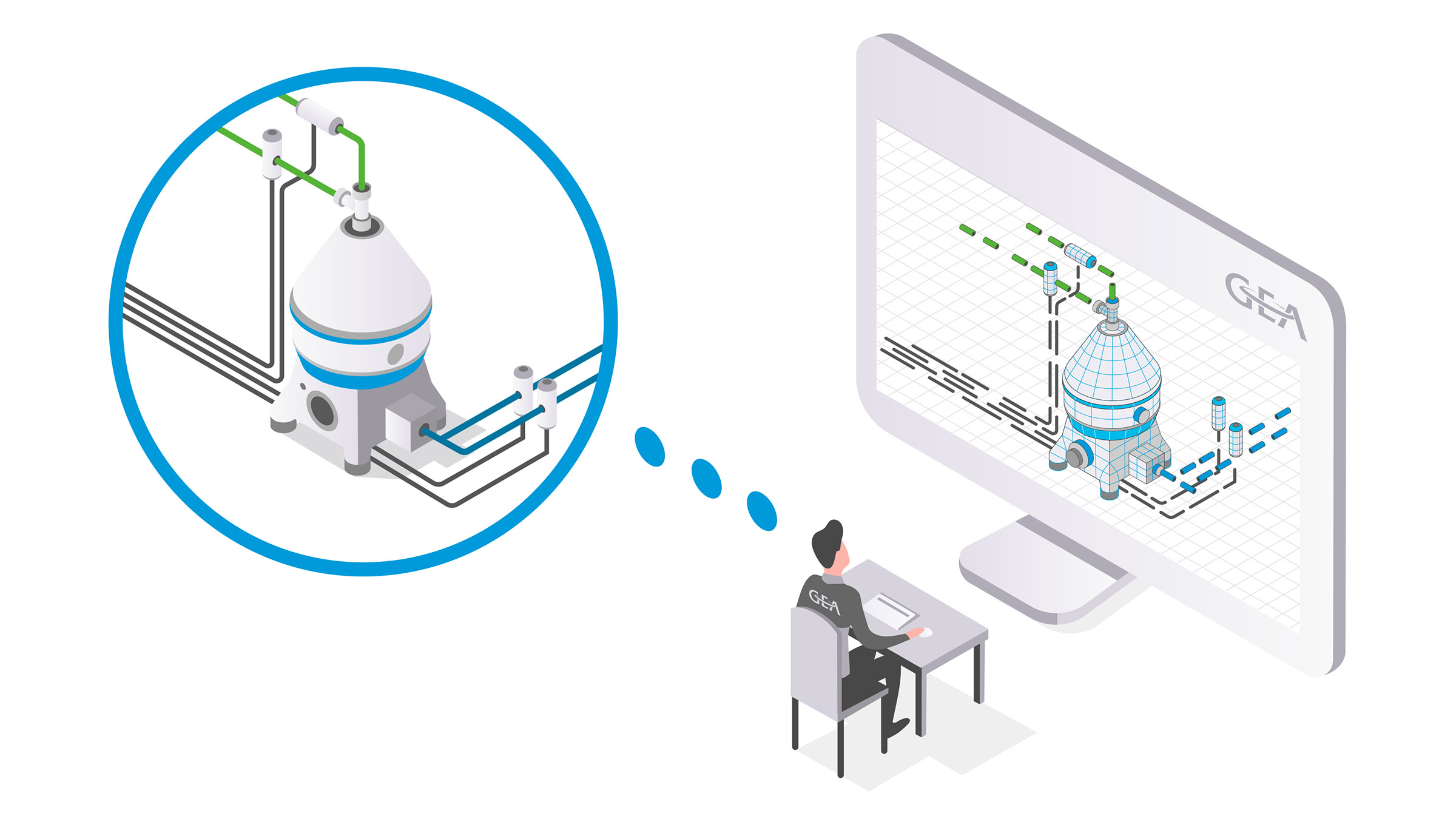

Simulation

Even small installations are becoming increasingly complex. Unexpected challenges often escalate commissioning procedures. Virtual commissioning by simulating a complete separator installation using a digital twin avoids additional time and costs.

The control system GEA IO has been designed as intuitive as possible. Displays have been consistently streamlined, the symbols are self-explanatory, and the color code is based on international standards.

GEA IO for all GEA Separators and Decanters

Next to control and display reliable data, GEA IO is able to capture and evaluate data. GEA IO ensures a safe and reliable operation to maximize the performance and availability of your centrifuge.

Preventive service indication

Size matters

GEA IO installed on a decanter