Dairy Ingredients

IMPORTANT NUTRITIONAL SUPPLEMENTS AND INGREDIENTS

Plants for processing dairy derivatives, including milk and whey

GEA offers complete solutions for:

- Casein / Caseinate Powder

- Cheese Powder

- Lactose Powder

- Milk Lactoferrin

- MPC / MPI Powder (Milk Protein Concentrate / Isolate)

- Yoghurt Powder

- Whey & Milk Permeate Powder

- WPC / WPI Powder (Whey protein Concentrate / Isolate)

- Whey Powder

GEA has decades of industry, application technology, and engineering experience in the dairy ingredients processing sector. We are a global leader in the provision of complete processing plant including skimming, filtration, heat treatment, separation, drying and packaging technologies, and components for manufacturing a wide range of diary ingredients products. Our technologies include a patent-pending microfiltration system, and a proprietary spray drying control technology for precisely controlling dairy ingredients powder moisture content.

Our expertise in the design, construction and installation of complete plants, and systems enables GEA to design seamless, end-to-end processing solutions for a wide range of dairy ingredients products, from high volume protein powders to custom derivatives for specialized and niche markets.

GEA can oversee the whole plant design and construction project, from concept through to commissioning and production handover. And because we work closely with our clients, together we ensure that every consideration is addressed and every expectation met, from the potential effects of mechanical processing on product quality, to plant efficiency, sustainability, hygienic operation and automation.

Our global service teams can support our clients with tailored training programs as well as parts service and maintenance, plant optimization and upgrades to ensure clients can meet their future dairy ingredients processing needs.

Products & technologies

-

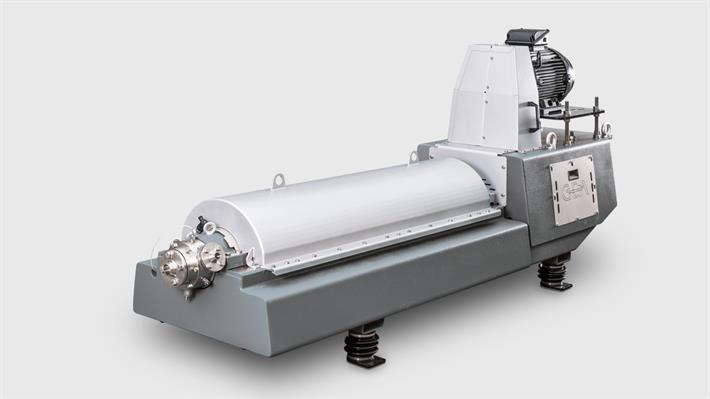

Showing 1 of 1Centrifuges & Separation EquipmentSince 1893, GEA has been building centrifuges which combine high separating efficiencies, clarifying efficiencies and throughput capacities with maximum savings in terms of energy, water and disposal costs.

Let's stay in touch!

Contact us