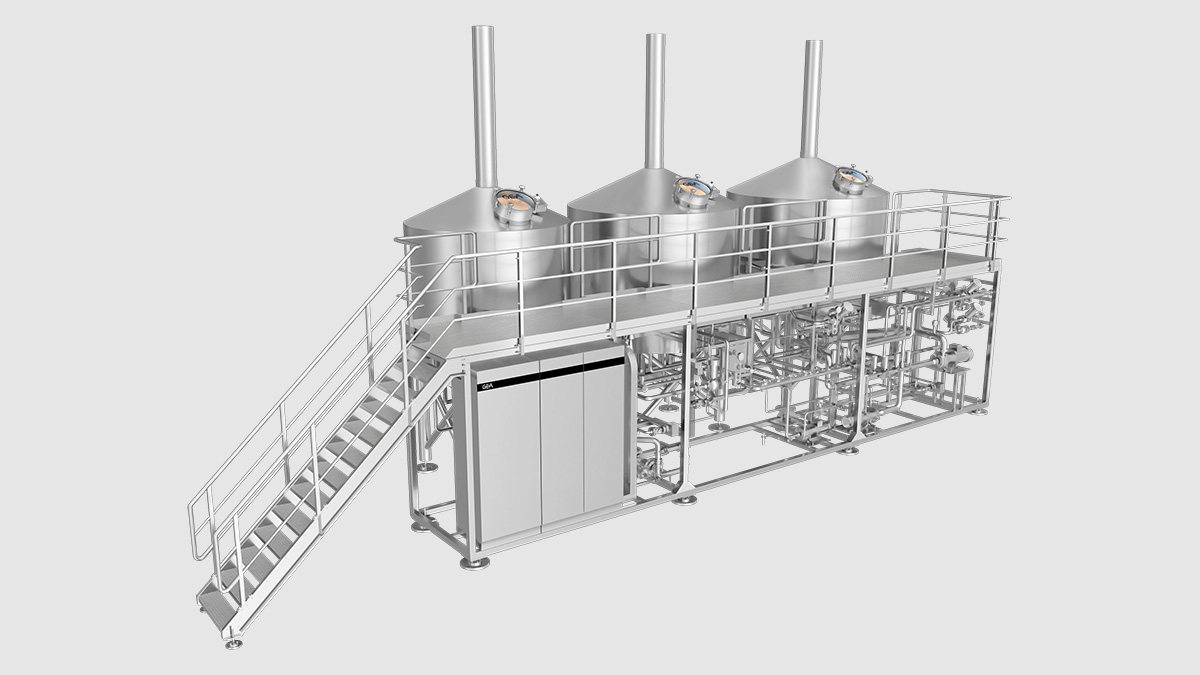

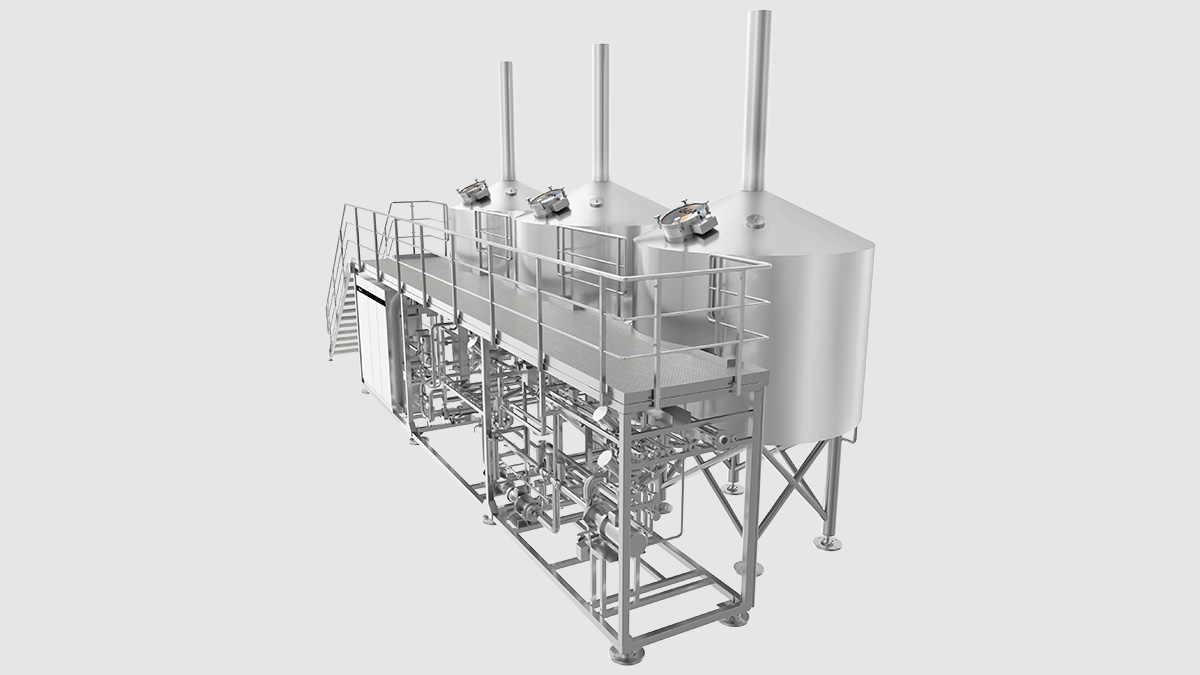

Designed for a batch size of 40 hl (35 U.S. bbl)

GEA CRAFT-STAR® BREWHOUSE XL

With a striking visual appearance and a clear focus on specialty beer recipes, the CRAFT-STAR® XL is the right tool for the mid-sized craft brewer wishing to produce 40 hl of the finest wort in any style.

GEA´s state-of-the art brewing technologies gives you unsurpassed efficiency in the use of raw materials. And, thanks to the all stainless steel design, reliable components and solid craftsmanship, this sturdy workhorse brewery will serve you for many, many years.

Key benefits of the CRAFT-STAR® XL craft brewhouse

- Pre-engineered brewhouse concept is cost-effective and offers short lead times

- Versatile, over-sized vessels can handle high gravity beer recipes

- Easy to install and set up

- Flanged connections to utilities make for easy on site tie-ins

- External wort boiling allows for maximum batch size flexibility

- Highly efficient: up to 98% extract yield in the lauter tun

- Up to 5 or 7 brews within 24 hours means high throughputs, even in a one-shift operation

- Compatible with infusion and decoction mashing regimes

Fully equipped for every application

Compact and easy to ship, the CRAFT-STAR® XL complies with highest safety standards. Integrated systems monitor the differential pressure and provide full control of the lautering process, and the automated GEARBOXX® ensures repeatable batch production, process visualization and remote support. Further design elements include

- a grist hydrator and mash agitator

- a trub dam to handle high hop loads

- a central media interface and water mixer

- a built-in CIP manifold for semi-automated cleaning.

Available configurations and batch sizes

- Sized for 40 hl (35 US bbl) hot cast-out wort volume

- Choice of 2-, 3- and 4-vessel brewhouse configuration

- Toolbox includes mash tun kettle, lauter tun, mash/lauter tun, kettle/whirlpool and an extra whirlpool

- Can be upgraded with GEA MILLSTAR® wet milling technology for maximum plant performance

- Various add-ons available: vapor condenser, dosing equipment, spent grain handling, wort cooling/aeration, water supply skids, etc.

- Choice of attractive polished or matte vessel surface finishes

Let's stay in touch!

Contact us