Homogenizing valves

HOMOGENIZING NANOVALVE HP

The innovative technology of NanoVALVE®HP can reach optimized results in terms of homogenization effects in different fields of applications, such as: vaccines, parenteral nutrition, nanocellulose and products containing additives, flavorings and stabilizers.

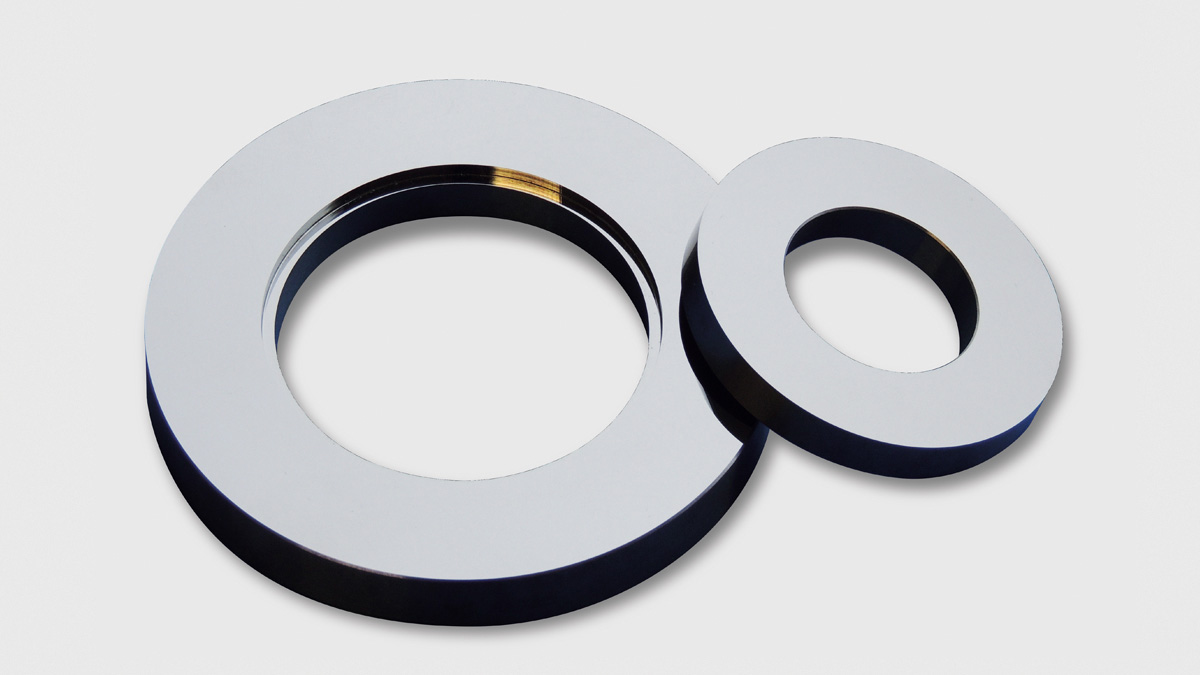

Revolutionary design

Maintaining the same process conditions, NanoVALVE®HP is now able to achieve an excellent homogenization quality, making the effects on the finished product even more recognizable. In addition, with the same homogenization level, it allows working at lower pressures related to conventional valves.

The geometry of the valve is based on a specific profile capable of optimizing the distance between the passage head and the impact head and therefore to allow a greater efficiency of the fluid dynamic forces.

Reimagine liquids

It may surprise you how many products need homogenization in their manufacturing process to make them more compatible with your daily life. Stabilization and a longer shelf life have always been among the highest priorities in many different processing industries but, especially nowadays, as lifestyles continue to change rapidly, they are becoming more and more valued.

Technical features

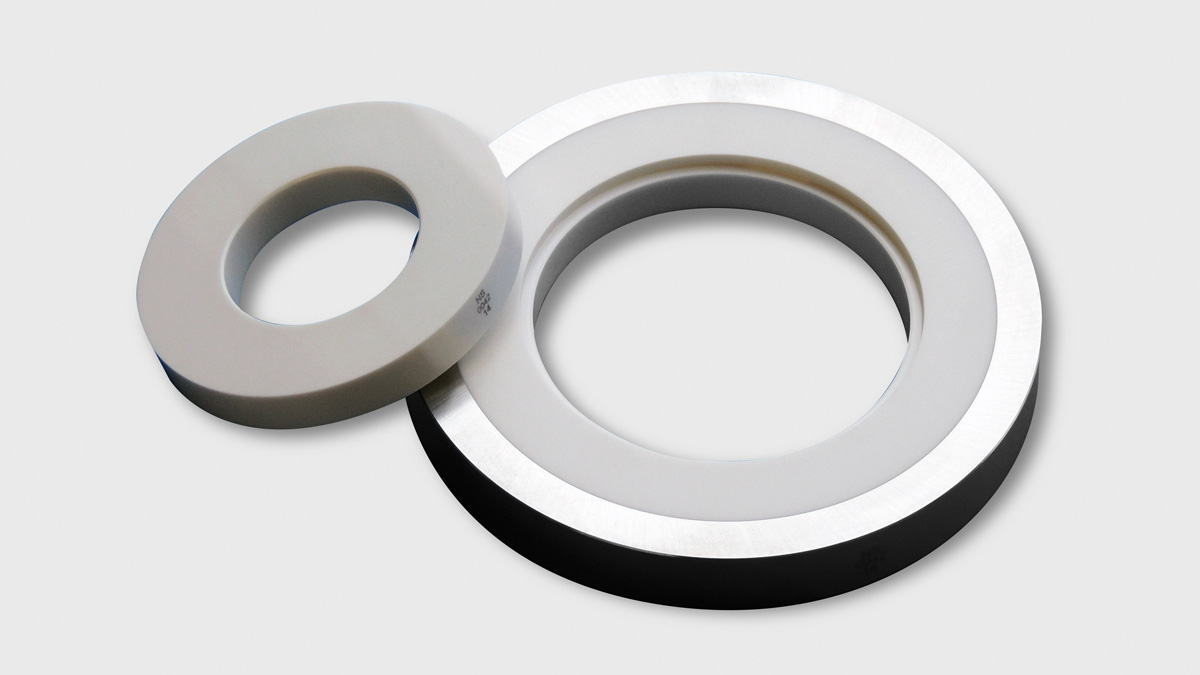

NanoVALVE®HP is available in 3 sizes, thus offering the possibility to combine different valve parameters: the passage head, the impact ring and the travel, which can be customized according to the needs of the process.

Another revolutionary feature of this valve regards the impact ring, fully integrated into the passage head, so as to form a valve composed of only two parts: the passage head and the impact head, both reversible.

NanoVALVE®HP is available on models of the Ariete® Series, from NS3090 to NS5355 for operating pressures between 250 and 700 bar and flow rate range from 5.000 to 31.000 l/h.

Downloads

Let's stay in touch!

Contact us