Membrane Filtration Systems

MEMBRANE FILTRATION SYSTEMS

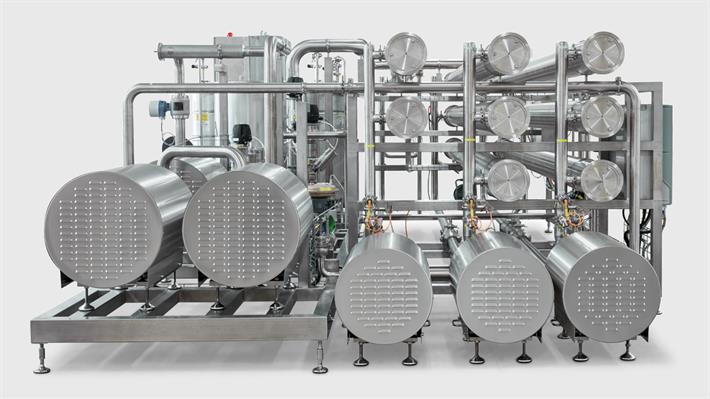

Cross-flow membrane filtration, including nanofiltration, microfiltration, ultrafiltration and reverse osmosis, is the technology of choice for many industrial processes that require the separation or concentration of products without the application of heat. There are applications throughout the food, dairy, beverage, chemical, biotechnology, fermentation, as well as starch and sweetener industries in which membrane filtration excels.

Products

Showing

Let's stay in touch!

Learn more about innovations and our products, by signing up to our newsletter.

Contact us

We are here to help! With just a few details we will be able to respond to your inquiry.