The solution for specific tasks

HYGHSPIN ENGINEERED

Twin-screw pumps from the HYGHSPIN series are the perfect solutions for countless applications

Innovative and hygienic design, highly economical, optimum MTTR value – main reasons for HYGHSPIN.

The HYGHSPIN stainless steel pump series from Jung Process Systems have been proved worldwide and can be used for flowable products with practically all viscosities and consistencies – whether aqueous, highly viscous, lumpy, fibrous, or gas-laden.

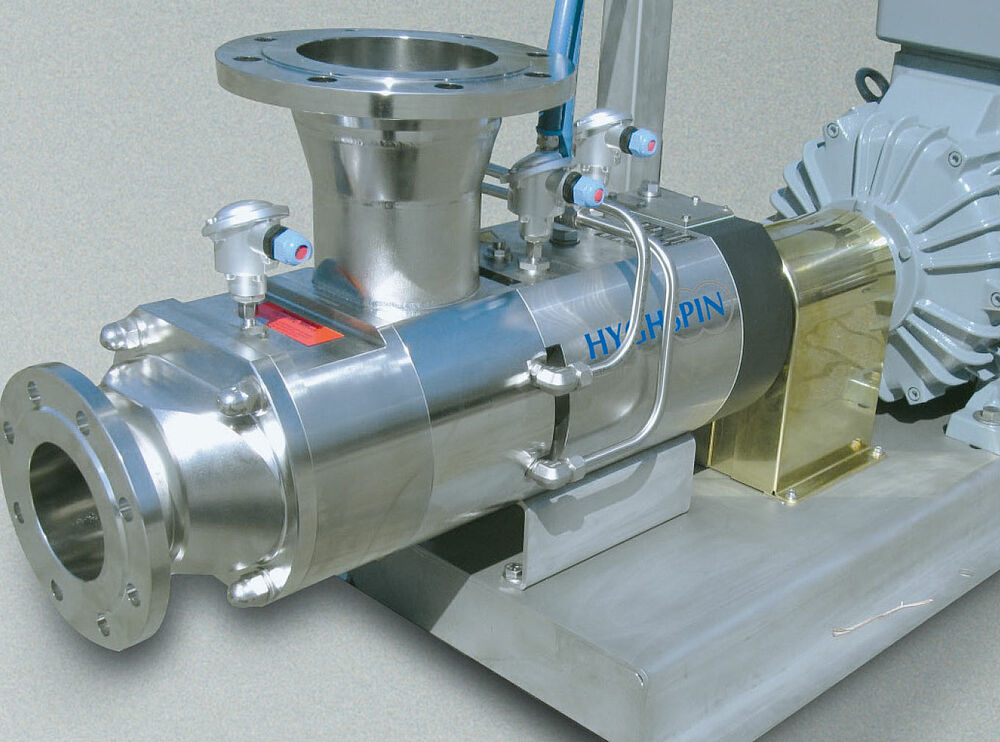

HYGHSPIN Engineered twin-screw pump – the solution for specific tasks

Individual and economic

HYGHSPIN Engineered solutions are based on the different versions of the HYGHSPIN series. Hereby, your requirements come first. With a HYGHSPIN Engineered solution, we supply the precise version with the accessories you need. Numerous special solutions are possible. Whether special (heated) couplings, pump housing seals with vapour barrier, special materials, or mobile units complete with controls – together with you we find the optimum version for your application.

HYGHSPIN Engineered solutions are available in sizes of 70, 90, 105 and 125. Max. pumping volume is about 350 m³/h. Pressure difference is up to 50 bar.

HYGHSPIN Engineered - Individual solutions for special tasks

-

Advantages at a glance

- Customer-specific versions acc. to your requirements

e.g. special connections, heated inlet & outlet connections, vapour barrier housings - Increased corrosion resistance

Use of special materials such as Duplex 1.4462, 1.4539, or Hastelloy - Increased wear resistance

Use of special hardening processes and coatings - Pump units with expanded scopes of delivery

e.g. mobile units with controls, containers, or measurement equipment

Moreover, all the other advantages of HYGHSPIN twin-screw pumps apply

- Considerable cost savings

Reduced investment and maintenance costs - Best quality

Made completely of stainless steel - Exceptional service-friendliness

The pump must not be removed from the plant for maintenance work - Utmost flexibility

A wide range of products, viscosities, and quantities can be handled with a single pump - Pumping is gentle and smooth

Low speed, minimum pulsation, no pressure surges - Utmost hygiene level

No dead spaces, and particularly good flushing of the shaft seal - CIP and SIP:

Cleaning and sterilisation within the plant, use as CIP feed pump

- Customer-specific versions acc. to your requirements

Downloads

Let's stay in touch!

Contact us